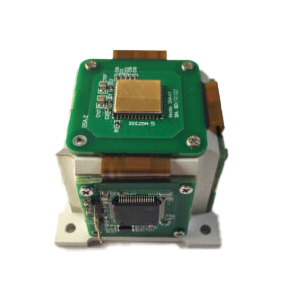

High-Precision CAN Bus Non-Contact Angle Sensor

Introduction

ER-AS-25 adopts the combination of embedded microprocessor and numerical control angle second-level calibration device, and adopts program calibration conversion to realize the characteristics of high precision, low temperature drift and low power consumption. Achieve CAN bus protocol, 100HZ output frequency, high resolution 0.015°, full range accuracy 0.05°.

The angle sensor uses MEMS technology to integrate the nano magnetic cluster thin film material and the differential array magnetic sensor element to produce a non-contact induction rotating magnetic field change. The system integrates a microcomputer, voltage and current transmitters and various circuit protections. Programmable intelligent control is set by DSP processing, linearity correction, temperature compensation, output signal standardization according to range, digital filtering, zero setting and multi-level different slopes.

The product has the characteristics of non-contact, long life, high resolution, low temperature drift, good linearity, fine reset, high frequency response, multiple protections, anti-interference, anti-vibration, and anti-shock characteristics, that is suitable for water, oil, gas, vibration, shock, especially harsh industrial environments, are also ideal alternatives to contact angle sensors (such as conductive plastic potentiometers).

Features

Sampling rate: 1K HZ

Full range accuracy 0.05°

Output CAN bus

Wide voltage input DC 9~36V

Wide temperature working -40~+85℃

Angular resolution is 0.015°

High vibration resistance>20000g

IP66 protection level

Range 0~360°(optional)

Linearity is 0.15%~0.5%

Applications

Railway gauge

Satellite solar antenna positioning

Towed motor control

Mining machinery, oil logging equipment

Medical equipment

Liquid valve: angle actuators

Angle-based control

Various construction machinery angle control

Textile machinery

Specifications

| Parameter | Condition | ER-AS-25-90 | ER-AS-25-180 | ER-AS-25-270 | ER-AS-25-360 | Unit |

| Measuring range | / | 0~90 | 0~180 | 0~270 | 0~360 | ° |

| Temperature drift | -40~85° | ±0.0015 | ±0.0015 | ±0.0015 | ±0.0015 | °/℃ |

| Sensitivity temperature coefficient | -40~85° | <150 | <150 | <150 | <150 | ppm/℃ |

| Frequency response | DC response | 100 | 100 | 100 | 100 | Hz |

| Resolution | / | 0.012 | 0.012 | 0.012 | 0.012 | ° |

| Precision | -40~85℃ | 0.05 | 0.06 | 0.08 | 0.1 | ° |

| Long-term stability | -40~85℃ | 0.055 | 0.063 | 0.08 | 0.12 | ° |

| Output interface | / | CAN bus | ||||

| Power on start time | / | 0.2 | 0.2 | 0.2 | 0.2 | s |

| The response time | / | 0.01 | 0.01 | 0.01 | 0.01 | s |

| Average working time | ≥55,000 hours/time | |||||

| Impact resistant | 20000g, 0.5ms, 3 times/shaft | |||||

| Shock resistant | 10grms, 2~2000Hz | |||||

| The use of temperature | -40~85℃ | |||||

| Waterproof level | IP66 | |||||

| Cable | Standard 1.5m length, wear resistance, oil proof, wide temperature, shielding cable 4*0.3mm² | |||||

| Weight | 180g (excluding boxes) | |||||

Electrical indicators

| Parameters | Condition | Min | Typical Value | Max | Unit |

| The power supply voltage | / | 9 | 12 | 36 | V |

| Working current | / | / | 20 | / | mA |

| Reverse power protection | / | / | 40 | / | V |

| Signal reverse protection | / | / | 40 | / | V |

| The output load | Resistivity | / | 2 | / | kΩ |

| Working temperature | / | -40 | / | 85 | ℃ |

| Storage temperature | / | -55 | / | 100 | ℃ |

Application Techniques

1.Dip angle sensor method for measuring bridge deflection

2.Determination of Initial Attitude Angle of MEMS Inertial Sensor

3.What Performance is the Accelerometer Sensor in FOG North Finder

4.Calibration Method of Angular Velocity Sensor for Single-axis Speed Turntable

5.Principle and Characteristics of Angular Velocity Sensor

6.Analysis of Typical Applications of MEMS Sensors

More Products