In many fields, the application of quartz accelerometers usually has extremely high requirements for measurement accuracy and stability. In order to better meet these requirements, thinning has gradually become an important trend in the design and manufacturing process of quartz accelerometers. This is mainly because the thinning of quartz accelerometers helps to improve its measurement accuracy, and can better adapt to certain specific application requirements, and also benefit from the promotion of technological progress.

At the same time, the thinning of the quartz pendulum inside the quartz accelerometer is also to improve the performance and accuracy of the accelerometer. As the core component of the quartz accelerometer, the performance of the quartz pendulum directly affects the range and resolution of the accelerometer. Studies have shown that the thickness of the flexible beam is the determining factor of the pendulum's swing amount and vibration frequency. By reducing the thickness of the flexible beam, the performance of the pendulum can be optimized, thereby improving the accuracy and stability of the accelerometer. In addition, different quartz glass materials and surface defects will also affect the performance of the pendulum to varying degrees. Therefore, by adjusting the thickness of the flexible beam, the response characteristics and time stability of the accelerometer can be improved, making it more suitable for high-precision measurement and application.

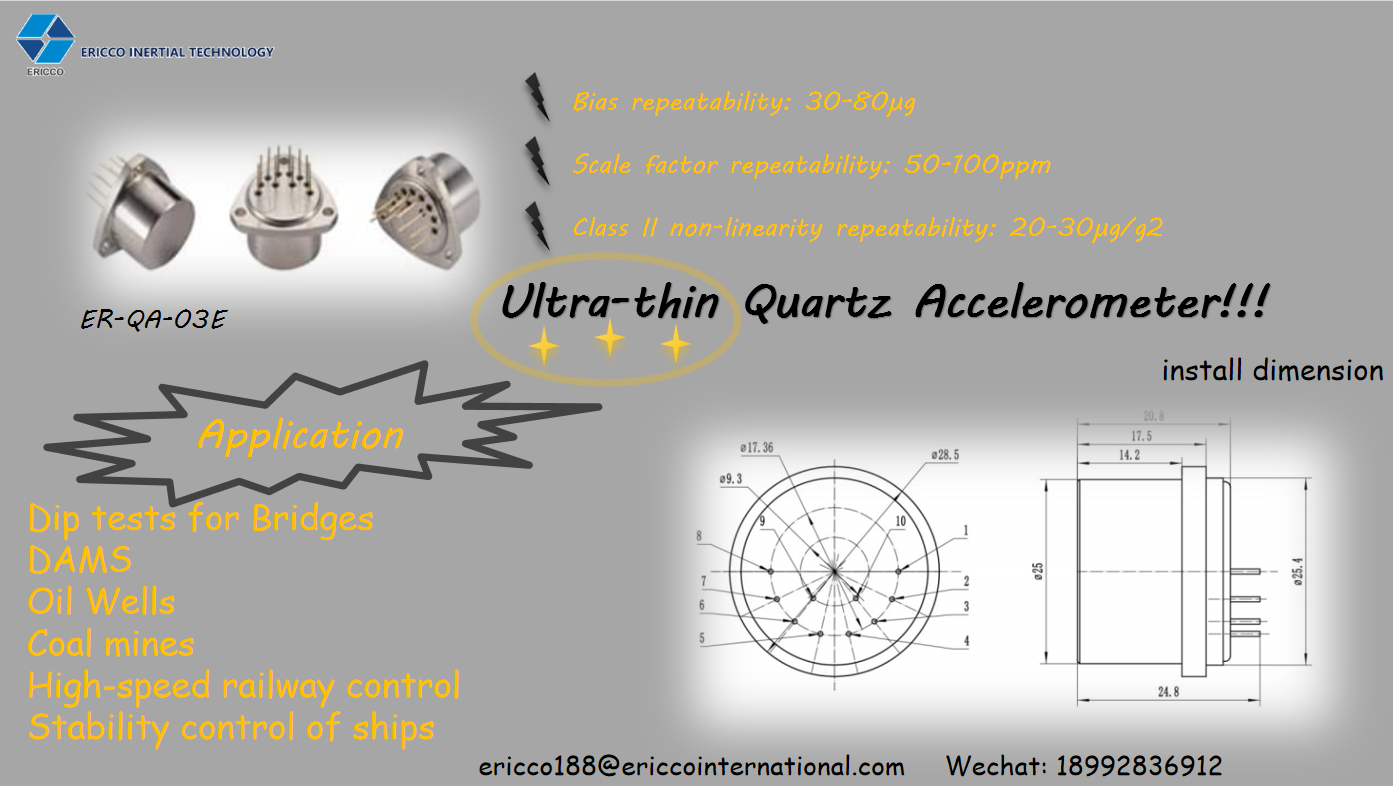

ERICCO happens to have an ultra-thin quartz accelerometer, the ER-QA-03E series. The ER-QA-03E ultra-thin quartz flexible accelerometer adopts a unique structural design and dedicated circuit. The product output current is linearly related to force or acceleration. Users can select the appropriate sampling resistor through calculation to achieve high-precision output. At the same time, they can also select a built-in temperature sensor according to user needs to compensate for the offset value and proportional coefficient and reduce the impact of ambient temperature.

For the 03E ultra-thin quartz accelerometer, its accuracy may not be as high as the 03A series, and the measurement range is not as large as the 03B series (±70g), but for many fields where quartz accelerometers can be used, it is sufficient to meet the needs of most application scenarios. The bias repeatability of the 03E series is 30-80μg, the scale factor repeatability is 50-100ppm, and the Class II non-linearity repeatability is 20-30μg/g2. If you are looking for an ultra-thin quartz accelerometer, you can give the 03E series a try!

If you have any questions about this product, or if you want to know anything about other products of our company, please feel free to contact me at any time, and you are also welcome to communicate with me in the comment area. You can also follow me and pay attention to my subsequent product recommendations. One day you will find the product you need here!

More Technical Questions

1. Full-temperature Performance Optimization Method For MEMS accelerometer

2. A Closed-loop Test Method for Damping Coefficient of Q-Flex Accelerometer

3. Driving Automotive Evolution: MEMS Accelerometers

4. Factors Affecting the Stability of Q-Flex Accelerometers

5. Structure Design of High Precision Quartz Flexible Accelerometer

6. Methods to Maintain the Long-Term Performance of Quartz Flexure Accelerometers