MEMS accelerometers use more materials, and different parts are likely to use different materials. For example, the substrate material used as a substrate, the mask material used as a mask, the sacrificial layer material used for surface micromachining, and so on. The materials commonly used in micro-accelerometers are monocrystalline silicon, silicon dioxide, silicon carbide, silicon nitride, polycrystalline silicon, etc., which specific material is used for which part is not fixed, it needs to be based on its physical and chemical properties and in the design process. The role of the accelerometer is considered comprehensively. Because the dynamic requirements of the sensor are relatively high, it is necessary to perform finite element analysis after the structural design is completed and the size of the structure is obtained.

With the continuous development of science and technology, microelectromechanical systems (MEMS) have been widely used in various fields. While MEMS materials are the basis of MEMS devices, their classification is becoming more and more important. Based on the properties and applications of MEMS materials, MEMS materials are classified and introduced.

1. Basic materials

Silicon material is one of the most commonly used materials in MEMS manufacturing, with excellent mechanical, optical and electrical properties. The advantage of silicon is its proven processing and reliability for applications such as sensors, micro-accelerometers and micro-manometers.

Glass materials have good optical transparency and chemical stability, and can be used to make optical devices and microfluidic devices. The applications of glass materials in MEMS field mainly include microlens, microchannel and microreactor.

Metal materials are often used to make electrodes and connecting wires in MEMS devices. Common metal materials. Including aluminum, copper and gold, with good electrical conductivity and reliability.

2. Functional materials

Piezoelectric materials are a class of materials that produce a charge distribution when subjected to mechanical stress. Piezoelectric materials are often used to make acoustic sensors, vibration sensors and microjets.

Magnetic materials are magnetic and can be used to make magnetic sensors, micromotors and magnetic memory. Common magnetic materials are ferrite and Ndfeb and so on.

Optical materials have good optical properties and are suitable for making optical devices and optical sensors. Common optical materials are condensers and semiconductor materials.

3. Packaging materials

Polymer materials have good insulation and mechanical properties, which are suitable for making packaging shells and sealing materials. Common polymer materials are polyimide and epoxy resin.

Metal materials are often used in MEMS packages to make leads and package shells. Common metal materials are copper, nickel and titanium.

4. Special materials

Biomaterials play an important role in MEMS applications in the biomedical field. Biomaterials have good biocompatibility and bioactivity, and are suitable for making biosensors and biochips.

Nanomaterials have special physical and chemical properties and can be used to make highly sensitive sensors and nanomachined devices. Common nanomaterials include carbon nanotubes and gold nanoparticles.

Using the finite element analysis software ANSYS to analyze the accelerometer model, the following results can be obtained:

(1) Perform a static analysis to find the part with the greatest stress.

(2) Perform modal analysis to obtain the natural frequency of the structure and the vibration modes at each natural frequency.

(3) Transient dynamic analysis can obtain the structure's response to external excitation.

Through the results of the above finite element analysis, the design can be further improved, so that the designed accelerometer has better performance.

If you want to get more details about MEMS accelerometer,pls visit https://www.ericcointernational.com/accelerometer/mems-accelerometer/

More Technical Questions

1.MEMS Accelerometer Packaging Technology

2.Calibration Method of Accelerometer

3.How to Improve the Long-term Stability of the Quartz Accelerometer?

4.What is the Effect of Temperature Coefficient on Quartz Accelerometer?

5.What are the Advantages and Disadvantages of Quartz Accelerometers?

6.Quartz Accelerometer VS MEMS Accelerometer

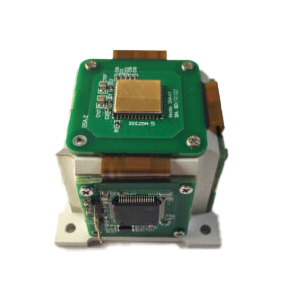

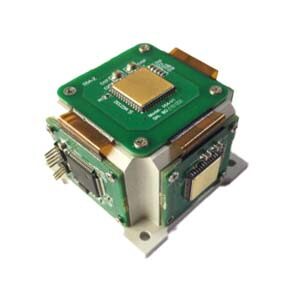

Products in Article