MEMS gyroscope technology is a great technological invention in the 21st century. Its emergence provides new options for many industries. MEMS gyroscope can be used in many fields, such as oil logging, aerospace, drones, mining and surveying, etc. MEMS technology has been constantly improving. However, no matter how advanced the technology is, there will still be errors, and calibration errors are a very important part of MEMS technology.

MEMS gyroscope error

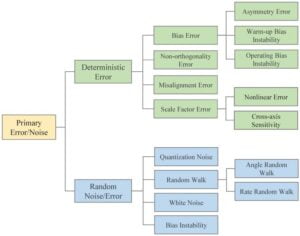

Like any physical sensor, gyroscopes are subject to measurement errors. The errors of MEMS gyroscope can be roughly divided into deterministic errors and random errors. Random errors include turn-on errors, random noise, and drift caused by long-term operation, which are difficult to compensate for. Deterministic errors are caused by inaccurate factory calibration (or incorrect conversion parameters in the accelerometer data sheet) and include scale factor errors, bias, non-orthogonality errors, temperature-related data drift errors, etc.

Due to the smaller size of MEMS, its accuracy is lower than that of some larger sensors. Therefore, deterministic errors have a greater impact on MEMS inertial sensors. From the perspective of hardware structure, MEMS gyroscopes are mostly made of silicon. Silicon is a temperature-sensitive material, and its physical properties vary greatly with temperature. This is also an important factor causing offset thermal drift and scaling factors, among which offset thermal drift is more dominant. In addition, some errors caused by changes in the external environment (such as altitude and local and temporal changes in gravitational acceleration) can also be compensated by recalibration of the sensor. Figure 1 lists some important errors and noise of MEMS inertial sensors.

Figure 1 some important errors and noise of MEMS inertial sensor

Calibration of MEMS gyroscope

Each MEMS gyroscope undergoes rigorous performance testing and calibration of sensitivity and zero-rate output values before leaving the factory.

Calibration is to solve the error coefficient by comparing the difference between the actual measurement output of the sensor and the preset reference value, and constructing the relationship between the measurement output and the expected output, so that the measurement output of the sensor tends to be consistent with the ideal output. According to the different preset reference values or reference objects, it can be divided into two categories: autonomous calibration and non-autonomous calibration. The specific difference lies in whether the assistance of high-precision laboratory equipment is needed, that is, error calibration through attitude reference data provided by large precision instruments.

1. Non-autonomous calibration: This kind of calibration requires the assistance of well-structured precision instruments, such as high-precision turntables, centrifuges, shakers, etc.

2. Autonomous calibration: This calibration is completed using external reference excitations provided by the local gravity field, earth rotation angular velocity, uniform magnetic field, etc. without the assistance of high-precision instruments.

The specific calibration method will be introduced in detail in the next article.

If you want to know more about MEMS gyroscope, please click on the related products and related links below.

More Technical Questions

1.The materials and structure of MEMS gyroscope

2.What’s the advantages and disadvantages of MEMS gyroscope?

3.MEMS gyroscope VS FOG: What’s the difference between them?

4.The Calibration Method of High Precision MEMS Gyro

5.How to Improve the Sensitivity of MEMS Gyroscope?

6.How to Weld and Install High Performance MEMS Gyro

Products in Article

.jpg)