Quartz flexible accelerometer, as a classic high-precision mechanical pendulum accelerometer, is one of the key components in the field of high-precision applications. Quartz flexible accelerometer has been developed for more than 50 years, it is in the mid-1960s with the development of low-cost inertial navigation system requirements, developed on the basis of mature liquid floating pendulum accelerometer non-liquid floating dry accelerometer. The liquid floating pendulum accelerometer is large, the processing and assembly process requirements are very strict, the sealing requirements are very high, and the cost is high. Because the quartz flexible accelerometer adopts flexible support technology, the structure and process are greatly simplified, and the accuracy and reliability have fully met the application requirements of modern inertial navigation systems, so the production is more widely used.

1.Structural design

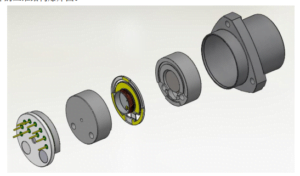

Pendulum accelerometer with flexible support.The pendulum assembly is connected with the instrument housing by two flexible rods.The bending stiffness of the flexible bar around the output shaft is very low, while the stiffness in other directions is very high.Its basic working principle is similar to that of a liquid pendulum accelerometer.The system has a high - gain servo amplifier that keeps the pendulum assembly operating near zero.In this way, the bending of the flexible bar is very small and the introduced elastic moment is also small, so the meter can achieve very high accuracy.This type of accelerometer is available in oil filled type and dry type.The oil-filled type is filled with high viscosity liquid as damping liquid, which can improve the dynamic characteristics of the instrument and enhance the anti-vibration and anti-impact ability.The dry accelerometer adopts electromagnetic damping or air film damping, which facilitates miniaturization, reduces costs and shortens startup time, but the accuracy is lower than that of the oil-filled accelerometer.

Figure :Three-dimensional structure diagram of quartz flexible accelerometer

2.Factors affecting the performance of quartz flexible accelerometer

There are many precise mechanical parts in the quartz flexible accelerometer. As the core part of the accelerometer, the dial head plays a decisive role in the range and performance of the accelerometer. The two indexes of measuring the accuracy of the accelerometer are mainly zero offset value and scale factor stability, which can reflect the comprehensive performance of the accuracy of the accelerometer. Analyzing the influencing factors is very important to improve the accuracy of the accelerometer.

2.1 Stiffness of quartz flexible beam

The pendulum component of the accelerometer is supported by two parallel quartz flexible beams. This design allows the flexible beam to be considered as pure bending when the Angle is shifted, that is, the stiffness is very small in the direction of the input axis and very large in the direction perpendicular to the input direction. When the pendulum component of the accelerometer moves, the capacitor position sensor will detect the offset of the pendulum component, feed back to the meter head circuit and output the feedback current to the torque coil, and the electromagnetic force will make the pendulum component return to the balance position. If the feedback moment or inertia moment is too large or too small, the pendulum component will be twisted. If the bending application cannot bear the torsional moment because of the quartz flexible beam material, the pendulum component will produce angular oscillation of the gas film, which is a very dangerous and destructive phenomenon.

Therefore, the range of quartz flexible pendulum acceleration will be affected by the stiffness of the flexible beam. The flexible beam of the existing accelerometer is designed according to the range standard of ±30g ~ ±60g, and the small-range accelerometer requires much smaller sensitive acceleration and high resolution, so the thickness and width of the flexible beam can be appropriately reduced, thereby reducing the stiffness of the flexible beam.

2.2 Magnetic induction intensity of permanent magnet

The magnetic induction intensity of permanent magnet materials is not constant, and it will be interfered with by various external environments. When the temperature rises, the magnetic induction intensity decreases. On the contrary, the magnetic induction intensity increases. But its variation is nonlinear, its magnetic induction intensity temperature repeatability is very poor, which has a great impact on the overall performance of the torquer. At the same time, the magnetic induction intensity of permanent magnets will also weaken with the change of time. Therefore, the stability of permanent magnet is also a major factor affecting the stability of accelerometer. At the same time, after the permanent magnet is magnetized, its magnetic field can not be changed, which makes the quartz flexible accelerometer relatively poor ability to adapt to the environment. Therefore, in order to improve the accuracy of the accelerometer, it is necessary to improve the design of the torque field.

2.3 Temperature

When the quartz flexible pendulum accelerometer is working, the internal temperature of the accelerometer will increase, and the torque coil will heat itself when passing the feedback current, which will also cause the temperature change of the meter head. Temperature is the main factor affecting the scale factor and zero deviation of quartz flexible pendulum accelerometer. In order to meet the accuracy requirements of the airborne gravimeter for the accelerometer, it is necessary to control the temperature of the accelerometer.

2.4 Damping interference

In quartz flexible pendulum acceleration, air damping is the most important damping, in addition to some electromagnetic damping generated by the torque coil. The formation of electromagnetic damping is because when the pendulum component swings up and down, the magnetic field of the working gap of the torquer will act on the coil of the pendulum component, generating induced voltage and current. Therefore, the internal damping interference is also a factor affecting the resolution of the quartz flexible pendulum accelerometer.

3.Summary

Through the above content, learn about the structural design of the flexible accelerometer and the factors that affect the performance, among many manufacturers, ericco stands out in the market with high-quality accelerometer products, with ER-QA-03A as the representative of high performance, its bias repeatability is 10-50μg and scale factor repeatability is 15-50 ppm ,it is that integrates accuracy and reliability.

More Technical Questions

1.Calibration Method of Accelerometer

2.How to Improve the Long-term Stability of the Quartz Accelerometer?

3.What is the Effect of Temperature Coefficient on Quartz Accelerometer?

4. What is Sensitivity and Measurement Range in Quartz Accelerometer?

5.Quartz Accelerometer VS MEMS Accelerometer

6.MEMS Accelerometer Packaging Technology

Products in Article