In drilling work, the measurement position of traditional inclinometers is far away from the drill bit, and the measured information has errors, and it is impossible to obtain accurate wellbore trajectory information, which will affect the entire drilling process.

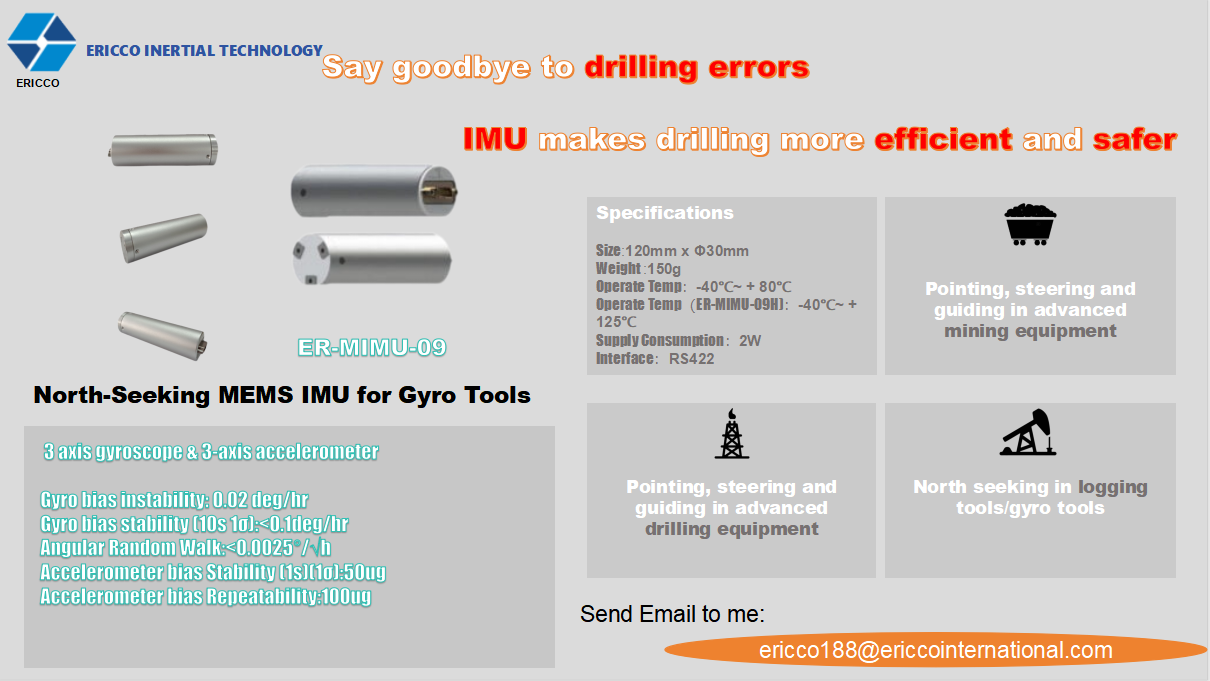

ERICCO's IMU ER-MIMU-09, with its unique cylindrical shape, can be directly installed in the drilling rig probe, measure the acceleration and angular velocity of the drill tool in real time, and obtain the drill tool's posture and speed information through calculation, greatly improving the measurement accuracy.

**Near-drill-bit installation**

The cylindrical shape, 120mm in length and only 30mm in diameter, can be placed directly near the drill bit or in the drilling rig probe. This allows drilling engineers to more accurately understand the position and posture of the drill bit, adjust drilling parameters in time, and ensure the safety and efficiency of the drilling process.

**High precision, high performance**

Equipped with high-performance three-axis MEMS gyroscope and three-axis accelerometer, it has small size, excellent performance and high measurement accuracy. The built-in gyroscope bias instability is 0.01deg/hr, and the angular velocity random walk is 0.0025°/√h. The accelerometer bias stability is 50ug, and the bias repeatability is 100ug.

**Drilling attitude monitoring and adjustment**

During the drilling process, IMU can monitor the attitude changes of the drill bit in real time. Once the attitude is abnormal or deviates from the predetermined trajectory, the drilling engineer can immediately take measures to adjust it to ensure that the drill bit can drill along the predetermined trajectory. This not only improves drilling efficiency, but also reduces the risk of drilling accidents.

**Strong environmental adaptability**

It has good impact and vibration resistance and is not affected by magnetic fields. We have also designed a high-temperature type that can accurately output angular rate information and acceleration information within a wider full temperature range, which provides new solutions for oil drilling logging, mining and other fields.

More Technical Questions

1.Technical innovation of north finder in directional drilling

2.Effective combination of MEMS technology and north seeker

3.Research on orthogonal monitoring technology of north finder

4.Modeling and filtering in signals collected by FOG north seekers

5.Error Modeling and Compensation Analysis of North Finder Based on FFT

6.Research and use of north finder for mining drilling rigs