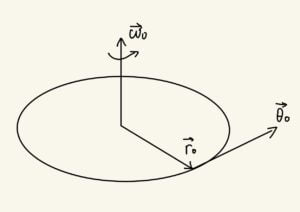

MEMS gyro is a device that measures the angular velocity of an object. MEMS is the abbreviation of micro-electromechanical system. It is based on the Coriolis force, an effect that creates a force that acts on a moving mass in a rotating system. The force produced is perpendicular to the mass's velocity and axis of rotation. MEMS gyroscopes measure the Coriolis effect to determine the angular velocity, or rate of rotation of a system. The Coriolis force effect is shown in the figure below.

Figure 1. The working principle of Coriolis force

Widely used MEMS gyros can be used in oil&gas, aerospace, marine, weapons, automotive, biomedical, environmental monitoring and other fields. And MEMS gyros have obvious advantages than traditional gyros:

1. Small size and light weight.

Suitable for installation space and weight requirements, such as missile load measurement. It is also suitable for special-shaped gyro tools. The drill pipes of many gyro tools require that the size of the gyro should not be too large, so MEMS gyros are a very suitable choice. Ericco’s MEMS gyro is all 11x11x2mm. For oil&gas industry, MG2-022 is specially designed for gyro tools which the temperature can reach 125 degrees compared with the highest temperature of 85 degrees from normal MEMS gyros.

2. Low cost.

MEMS gyro is a chip-based gyroscope, which is smaller and cheaper than traditional gyroscopes. It is a very good choice for companies and industries that need to control costs.

3. High reliability.

There are no rotating parts inside but all solid state devices. It can anti-large overload shock and has a long working life.

4. Low power consumption.

MEMS gyro consumes less power than mechanical gyroscopes, which is critical for battery-powered devices and energy-saving systems.

5. A large number of courses and easy to mass production

Suitable for high speed and large g value. Because MEMS gyro is small in size and low in cost, they are easier to mass produce.

6. Easy to digitize and intelligent.

Like digital output, temperature compensation, zero calibration, etc.

So what is the future development trend of MEMS gyroscopes?

MEMS technology is undergoing rapid changes, and its accuracy and performance are constantly improving to meet the needs of various fields. It is also officially due to the continuous advancement of MEMS technology that it has a place in the market today. In the future, MEMS gyroscopes will become smaller, more precise, and more energy-efficient. Many scholars are also developing new MEMS materials to cope with more application scenarios and challenges.

However, MEMS gyroscopes also have problems that need to be overcome, such as sensitivity to environmental factors of temperature, humidity, and vibration. Experts are also looking for various solutions to solve such problems. And the integration of MEMS gyroscopes as other modules is also a major trend in the future, such as IMU (Inertial Measurement Unit) and INS (Inertial Navigation System) devices based on MEMS gyroscopes.

Hope you will have a basic understanding of MEMS gyro. If you want to get more details about MEMS gyros, please read the relating articles and products below.

More Technical Questions

1.How accurate is MEMS gyroscope?

2.How to select MEMS gyroscope?

3.MEMS gyroscope VS FOG: What’s the difference between them?

4.What Are The Main Performance Parameters Of A MEMS Gyroscope

5.What’s the advantages and disadvantages of MEMS gyroscope?

6.ER-MG2-100 (0.02°/h) High Precision MEMS Gyroscope

Products in Article

.jpg)