1.What is an MWD instrument?

MWD instrument is the abbreviation of Measurement While Drilling, which means measuring instrument while drilling. MWD is an important member of the entire family of measuring instruments.

2.What does the measuring instrument measure?

The data obtained by the measuring instrument is the current well inclination, azimuth, and tool face of the current position near the downhole drill bit. What do these parameters mean? For example, these data can now be measured by ordinary mobile phones:

a.Well inclination (horizontal and vertical angle) is equivalent to measuring the horizontal and vertical state of the mobile phone, and the horizontal or vertical screen will be displayed on the mobile phone.

b.The azimuth (southeast, northwest) is equivalent to the compass of the mobile phone.

c.The tool surface of the instrument (how to turn the head up, down, left and right) is equivalent to some "720-degree panoramic websites" of the mobile phone, and the scene picture can be updated with the rotation of the mobile phone.

The measuring instrument integrates measurements such as well inclination, azimuth, and tool face.

3.What is measurement while drilling?

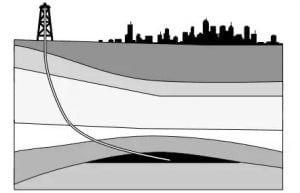

While drilling means relative to the traditional stop drilling. It is different from the method of wireline logging tools or other tools that "stop drilling" and then run down the measuring tools to obtain data.

The method of stopping drilling for drilling interval is equivalent to walking a few steps with eyes closed, stopping and opening eyes to see where it is. If there is a drilling-while-drilling technology, downhole data can be obtained in real time while drilling, and the specific location can be known. It's like walking with your eyes open.

4.Family history of measuring instruments

In the initial period, the measuring instrument may only be used to measure where the well is finally drilled. If there is no instrument that can control the trajectory, it can only be known but not controlled, and its role is limited.

Therefore, the development of measuring instruments is closely related to the development of trajectory-oriented control instruments. The more advanced the directional instrument is, the stronger the controllability is, and the higher the data quality requirements including the measurement frequency and accuracy are, which objectively promotes the development of the measurement instrument, so that the oil field can obtain greater production capacity within a certain space and time. Improve the efficiency of the oilfield industry. From the original chemical acid bottle method or physical striker method measuring instruments, photographic measuring instruments, electronic multi-point inclinometers to the latter submerged MWD and integrated MWD

(1) Drop-in MWD

The submersible MWD is an epoch-making product that realizes real-time measurement data transmission. One of the cutting-edge technicians of the instrument should be Anon of Schlumberger, who published a large number of papers on the development and improvement of MWD from 1981 to 1984.

Put a submersible MWD instrument into the valve seat in the drill collar before drilling, and then enter the well and drill normally. During the drilling process, the instrument transmits real-time measurement data to the ground.

Since there is no cable to transmit data, a modulation transmitter is designed into the instrument to transmit the data to the ground through pressure changes, and a pressure sensor is installed on the ground to demodulate the signal transmitted downhole and turn it into data that can be read by humans. Of course, without the power cable, the battery was redesigned into the instrument.

Such drop-in instruments are relatively easy to maintain and cost-effective for modern industry. Widely used in onshore oil fields. Some products of foreign companies had mature products in the 1990s. China research and development began in the late 1990s.

(2) Integrated MWD

The drop-in MWD combined with the drill collar becomes an integrated MWD. This equipment is an upgrade of a drop-in MWD. The driving force is the demand for logging while drilling equipment LWD and rotary steering equipment RSS matched with MWD.

What are these needs?

a.The addition of a power generation turbine module or the upgrade of a larger battery. As the pioneer of downhole equipment and the necessary equipment for basic data acquisition, MWD should provide LWD and RSS power to other equipment.

b.The generation of communication interfaces for other downhole instruments, and the hardware and software upgrades that need to communicate with other downhole equipment.

c.Integration of more sensors.

All of these require a larger volume of MWD, and the internal space of a large volume and a small drill collar is a contradiction, so the modules of the MWD are respectively fixed in a special drill collar in different shapes to save space. This is the integrated MWD.

As sensors become smaller and more variety, future products may be highly integrated with MWD, various LWD and rotary steering. If you want to know more information inside the wellbore. It is necessary to decentralize the addition of instruments in various positions of several kilometers of drill pipe. The smart drill pipe is still being developed and tested, so it is difficult to predict the commercialization time of future measuring instrument products

More Technical Questions

1.Three Signal Transmission Methods of MWD Inclinometer While Drilling

2.What Is The Difference Between MWD And LWD?

3.What Is The Principle Of MWD?

4.MWD Principle Introduction – Cable Transmission Method

5.Possible Problems And Solutions For Shallow Testing Of MWD Instruments

6.GWD – Gyro-while-drilling Technology Superior to Traditional MWD

Products in Article