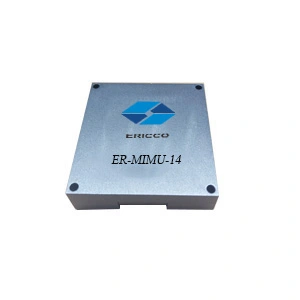

ER-MIMU-054 Low-Cost Attitude-control MEMS IMU

Introduction

Inertial Measurement Unit, referred to as IMU, is a device to measure the attitude angle (or angular velocity) and acceleration of the three axis of the object. Gyroscope and accelerometer are the core devices of inertial navigation system (INS). With the built-in accelerometer sensor and gyroscope, the IMU can measure the linear acceleration and rotation angular velocity from three directions and can obtain the attitude, velocity and displacement information of the carrier through the resolving.

ER-MIMU-054 uses MEMS accelerometer and gyroscope with high quality and reliability, RS422 and external communication. Default baud rate 921600 (customized). With X, Y, Z three-axis precision gyro, X, Y, Z three-axis accelerometer with high resolution, can be output by RS422 X, Y, Z three axis of gyroscope and accelerometer's original hexadecimal complement data (including gyro hexadecimal complement the numerical temperature, angle, the accelerometer hexadecimal temperature, the acceleration hexadecimal complement number); It can also output float dimensionless values of the gyroscope and accelerometer processed by the underlying calculation.

A simple operation is required to connect our products to your system and obtain IMU data without the 15-pin plug provided by our company. At the same time, the size and weight of our products can be significantly reduced by removing the base plate housing.

Features

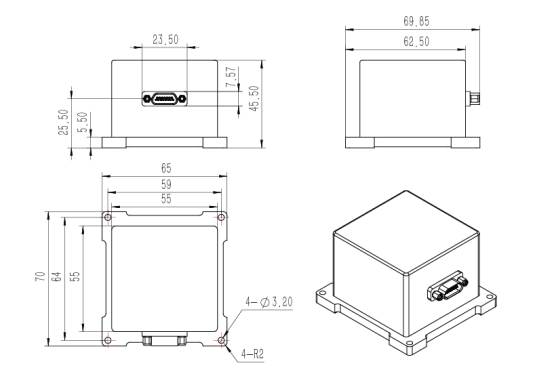

Size:70*65*45(with shell)/43.2*43.2*35.5 (without shell and baseboard)

Weight:220(with shell) /100(without shell and baseboard)

OEM modular design, strong applicability

-40~80°C temperature compensation

The product is low-cost

Gyro bias instability: 1deg/hr

Gyro bias stability (10s 1σ): 4deg/hr

Gyro angular random walk: 0.2 °/√h

Accelerometer bias repeatability: 100ug

Accelerometer bias stability (10s) (1σ): <50ug

Accelerometer class II non-linearity coefficient: <100ug/g²

Application

Robotic control & orientation in autonomous machines, unmanned vehicles

Azimuth, attitude, position measuring and keeping in GNSS-assisted INS

Pitch, roll measuring in AHRS for UAV

Motion survey and keeping in MRU

Attitude & azimuth keeping, positioning in IMU

Guidance, navigation, control in tactical MEMS system

Stabilizing & Pointing in satellite antenna, target tracking system

Specifications

| Item | Parameter | Unit | |

| Gyro performance | A | B | / |

| Range | 400 | 400 | deg/s |

| Scale Factor at 25°C | 20000 | 20000 | LSB/deg/s |

| Scale Factor VS Temperature (1σ) | 500 | 500 | ppm |

| Scale Factor Non-Linearity (1σ) | <200 | 200 | ppm |

| Bias Instability (1σ 25℃) | 3 | 1 | deg/hr |

| Bias Stability (10s 1σ) | 5 | 4 | deg/hr |

| Angular Random Walk | <0.25 | <0.2 | °/ √h |

| Bias Repeatability (1σ 25℃) | 5 | 4 | deg/hr |

| Accelerometer performance | |||

| Range | 30 | g | |

| Bias Stability (10s 1σ) | <50 | ug | |

| Bias Repeatability | 100 | ug | |

| Bias Temp Coefficient | <20 | ug/℃ | |

| Bias Temp Hysteresis | <1.5 | mg | |

| Scale Factor Non-linearity | <500 | ppm | |

| Scale Factor Repeatability | <30 | ppm | |

| Scale Factor Temp Coefficient | 10 | ppm/℃ | |

| Class II Non-linearity Coefficient | <100 | ug/g² | |

| Scale Factor | 250000 | Lsb/g | |

| Environment and power | |||

| Operate temperature | -40~+80 | ℃ | |

| Storage temperature | -55~+105 | ℃ | |

| Power supply | 6~12V | V | |

| Power (power supply 6V) | 2 | W | |

| Communication interface | RS-422 | ||

| Physical characteristics | |||

| Size | 70×65×45(with shell)43.2×43.2×35.5 (without shell and baseboard) | mm | |

| Weight | ≤220(with shell) ≤100(without shell and baseboard) | g | |

Dimension

Application Techniques

1.Do you know the core components that give precise control to automated equipment

2.High-performance IMU: A New Benchmark for Precise Measurement and Control

3.Industrial Versatile Tool: High Cost-Performance IMU Meets Diverse Needs

4.Flight safety secrets: The core role of high-precision IMUs in aviation

5.Revolutionizing drone navigation: How to redefine high performance and low cost

6.From flight control to fault diagnosis, how does IMU dominate drones?

Economical MEMS Gyroscope

Economical MEMS Gyroscope