ER-MG2-50/100 High Performance North-Seeking MEMS Gyro

Introduction

ER-MG2-50/100, a high performance MEMS gyro sensor with 0.01-0.02°/hr bias instability and 0.0025-0.005°/√hr angular

random walk, is specially designed for north seeking, pointing, initial alignment in logging tools/gyro tools,

mining/drilling equipment, UAV launch systems, satellite antenna, target tracking system and so on. Thanks to the

high performance, ER-MG2-50/100 can also used in high precision attitude measuring, stabilization control, positioning,

navigating in navigation grade MEMS IMU/INS, land surveying/land mobile mapping system, railway train system, etc. So

ER-MG2-50/100 is a best, cost effective, robust, reliable, small size, light weight, low power alternative of medium-low

navigation grade FOG DTG with north seeking, precision attitude measuring , inertial positioning and navigation

function.

The ER-MG2-50/100 High Performance North Seeking Gyroscope is a single-axis MEMS angular rate sensor (gyroscope) capable of measuring angular velocity up to a maximum of ±100°/s with digital output compliant to SPI slave mode 3 protocol. Angular rate data is presented as a 24-bit word.

The ER-MG2-50/100 is intended for north seeking applications. As an advanced, differential sensor design rejects the

influence of linear acceleration, enabling ER-MG2-50/100 to operate in exceedingly harsh environments where shock and

vibration are present.

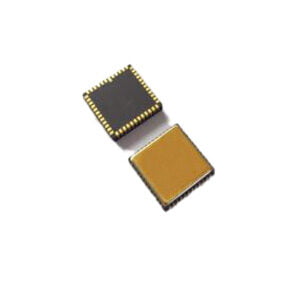

The ER-MG2-50/100 is available in a hermetically sealed ceramic LCC surface mount package, and is capable of operating

at 5V supply and a wide temperature range (−45°C to +85°C).

Features

Proven and robust silicon MEMS gyro

0.01-0.02°/hr bias instability

0.0025-0.005°/√hr angular random walk

Digital output (SPI slave)

5V operation (4.75~5.25V supply)

Low power consumption (35 mA)

High shock and vibration rejection

Hermetically sealed ceramic LCC surface mount package (11x11x2mm)

Integrated temperature sensor

RoHS compliant

Application areas

North seeking in logging tools/gyro tools

Pointing, steering and guiding in advanced mining/drilling equipment

Initial alignment/UAV launch systems

Direction pointing and tracking in satellite antenna, target tracking system

Guidance and navigation in navigation grade MEMS system

Orientating and positioning in railway train system

Precision platform attitude measuring and controls

Precision attitude, position measuring in navigation grade MEMS IMU/INS

North finding and positioning in land surveying/land mobile mapping system

Petroleum exploration

Bridge, tall building, tower, dam monitoring

Rock and soil monitoring

Mining

Specifications of North Seeking Gyroscope

| Parameters | ER-MG2-50 | ER-MG2-100 | Unit |

| Range | 50 | 100 | deg/s |

| Resolution | 24 | 24 | bits |

| Data rate | 2k | 2k | Hz |

| Group delay | 50 | 20 | ms |

| Bandwidth (-3dB) | 12 | 12 | Hz |

| Scale factor at 25°C | 160000 | 80000 | lsb/deg/s |

| Scale factor repeatability (1σ) | <50 | <100 | ppm |

| Scale factor vs temperature (1σ) | 300 | 300 | ppm |

| Scale factor non-linearity (1σ) | <200 | <300 | ppm |

| Bias instability | <0.01 | <0.02 | deg/hr |

| Bias stability (1σ 10s) | <0.05 | <0.1 | deg/hr |

| Bias stability (1σ 1s) | <0.15 | <0.3 | deg/hr |

| Bias repeatability (1σ) | <0.1 | <0.1 | deg/hr |

| Angular random walk | <0.0025 | <0.005 | °/√h |

| Bias error over temperature (1σ) | 3 | 3 | deg/Hr |

| Bias temperature variations, calibrated (1σ) | <0.1 | <0.3 | deg/Hr |

| Noise peak to peak | ±0.002 | ±0.003 | deg/s |

| G-Sensitivity | <0.5 | <1 | °/hr/g |

| Vibration rectification error | <0.5 | <1 | °/hr/g (rms) |

| Startup time | 1 | 1 | s |

| Sensor resonant frequency | 11~13 | K | |

| Environment, power and physical | |||

| Shock (charged) | 1000g, 1ms, half sine wave | ||

| Shock (uncharged) | 10000g, 1.0ms, half sine wave | ||

| Vibration (operating) | 12grms, 20Hz to 2KHz random vibration | ||

| Operating temperature | -45°C~85°C | ||

| Max storage (survival) temperature | -55°C~125°C | ||

| Supply voltage | 5±0.25V | ||

| Current consumption | 40mA | ||

| Synchronization mode | Default internal synchronization mode, external synchronization mode is optional | ||

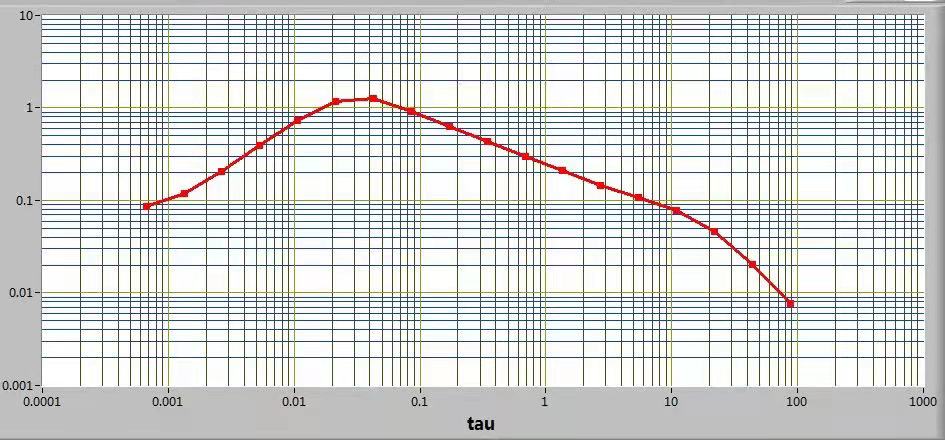

ER-MG2-100 ALLAN VARIANCE

Capable of measuring angular velocity up to a maximum of ±100°/s with digital output compliant to SPI slave mode 3 protocol.

The above information about north seeking gyroscope is provided by our engineers, if you want to know more, please contact us.

Application Techniques

1.Basic Knowledge of Bias Stability of MEMS Gyroscope

2.Classification And Performance Improvement Of MEMS Gyroscope

3.Comparison Of Technical Specifications Of Navigation Grade MEMS Gyroscope

4.MEMS Gyroscope: The Third Generation Of Gyroscopes Is Leading The Way

5.MEMS Gyroscope: Sensitive Structure | Detection Circuit | Integrated Package

6.Research On Segmented North Seeking Orientation Based On MEMS Gyroscope

More Products

.jpg)

High Accuracy Single-Axis MEMS Gyro

High Accuracy Single-Axis MEMS Gyro MEMS Triaxial North Seeker for Mining

MEMS Triaxial North Seeker for Mining