Main parameters of gyroscope

| Bias stability | ≤0.005°/h (100s Standard deviation) | |||||||

| Bias repeatability | ≤0.002°/h | |||||||

| Angular random walk | ≤0.0008°/√h | |||||||

| Magnetic field sensitivity | ≤0.001°/h/Gs | |||||||

| Total error of scale factor | ≤3ppm (1σ) | |||||||

| Measuring range | -500~500°/s | |||||||

| Start time | ≤5s | |||||||

| Operating temperature | –40℃~+65℃ | |||||||

| Storage temperature | –55℃~+85℃ | |||||||

| Shock | 30g/11ms(half-sine), 75g/6ms(sine) | |||||||

| Vibration | 7.2g/5min (3 directions) | |||||||

| Frequency(Hz) | 10 | 100 | 200 | 300 | 600 | 1000 | 2000 | |

| Power(g2/Hz) | 0.1 | 0.4 | 0.1 | 0.02 | 0.005 | 0.00003 | -6dB | |

| Jitter frequency | 420Hz~580Hz, the jitter frequency of type A, type B and type C gyroscopes decreases successively, which should be avoided in the design of system structure | |||||||

| Low pressure | Altitude 5000m | |||||||

| MTBF | 15000h | |||||||

| Storage life | 15a | |||||||

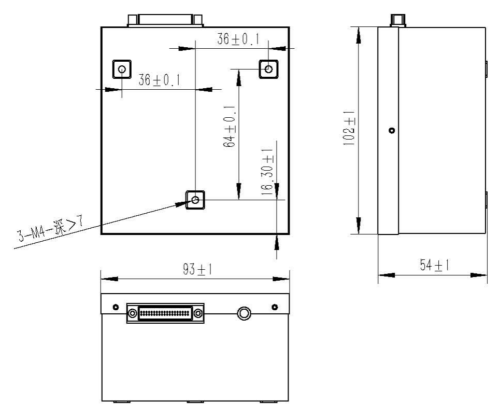

| Size | (102±1)mm×(93±1)mm×(54±1)mm | |||||||

| Weight | 0.95±0.1kg | |||||||

| Power consumption | ≤3W | |||||||

Mechanical interface

Figure 1 Shape and mounting dimensions of gyroscope

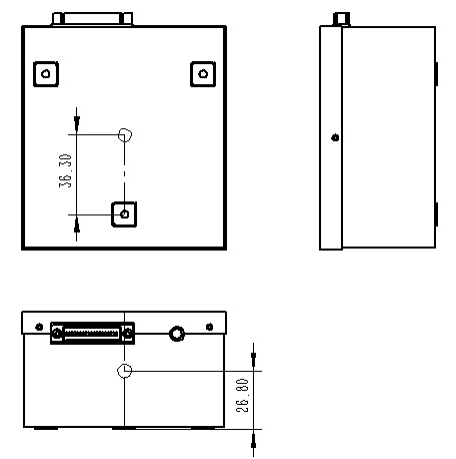

Mass center

Figure 2 Mass Center for gyroscope

Electrical interface

The electrical interface adopts J30J-37ZK socket, as defined in the following table.

| Node number | Name | Description |

| 17;35 | +15V | / |

| 18;36 | +15GND | Note that you can't connect to any other ground |

| 15;33 | 5VGND | / |

| 16;34 | +5V | / |

| 19;37 | -5V | / |

| 11;29 | AOUT | TTL output |

| 9;27 | BOUT | TTL output |

| 10;28 | ABGND | / |

| 14;32 | TCOM | Platinum resistance common end |

| 12 | Platinum resistance TMP1 | Gyro body, cathode attachment position |

| 30 | Platinum resistance TMP2 | Gyro box body, under the light prism |

| 13 | Platinum resistance TMP3 | Gyro body, near the pumping anode |

| 31 | Platinum resistance TMP4 | Gyro box body, near the box wall |

| 20;26 | GND | / |

| Other pins | Factory retention | / |

Cautions for use

- Gyroscope should be avoided by impact, knock;

- Gyroscopes with the same jitter frequency should be avoided in the same inertial navigation equipment;

- Pay attention to the use of spring pad when installing the gyroscope. It is recommended to use M4hex socket screw with grade 9 (including) or above, and the recommended torque value is 2.5NM.

Application Techniques

1.How does a ring laser gyroscope work?

2.What Is The Structure And Working Principle Of The Laser Gyroscope?

3.Laser Gyroscopes Shine In Many Fields Of Military And Civilian Use

4.Application of Laser Gyroscope

5.The Principle of Laser Gyroscope

6.China High Precision Laser Gyroscope

More Products