ER-MWD-38 Small Diameter Measurement While Drilling (MWD-Φ38mm)

Small Diameter Measurement While Drilling (MWD-Φ38mm) is a kind of small-path mud pulse wireless in-drilling inclinometer. This is a new product developed after ER-MWD-48 MWD. This product not only inherits the characteristics of ER-MWD-48 inclinometer with high precision, high stability and high vibration resistance, but also has a wider range of applications.

Features

1. ER-MWD-38 Measurement While Drilling can be used for the construction of conventional wellbore like the ER-MWD-48 Measurement While Drilling . Different diameters can be selected according to the conditions of on-site drilling tools (diameter of the drill collar Ф50.8mm, Ф71.4mm) Rubber wings to suit different drilling tools.

2. The external diameter of the instrument is Ф38mm. In the construction of small wellbore, the hole of the non-magnetic drilling tool may not be reamed (diameter of the drill collar is Ф50.8mm), which reduces the erosion of the drilling tool and enhances the safety of the downhole drilling tool.

3. When used in conventional large borehole construction, the muddy water circulation area of the non-magnetic drill collar is relatively increased, erosion of the drilling equipment and drilling tool is reduced, and the safety construction of the well team is facilitated.

4. It is more suitable for the second and third development of oil wells and small hole operations such as window sidetrack drilling. Also suitable for use with coiled tubing to connect MWD.

5. The underground electrical connection adopts self-locking air plug + cord connection, which makes the instrument connection convenient and reliable, and improves the reliability of the instrument.

6. The electronic chamber of the pulse generator and the gamma probe share a compression cylinder. The user can select conventional gamma or orientation gamma. Became one of the first manufacturers in China to use the Ф38mm outer diameter directional gamma wireless MWD system.

7. ER-MWD-48 and ER-MWD-38 are compatible with ground equipment, reducing the cost of using.

8. Ground equipment can be selected for wireless or wired transmission.

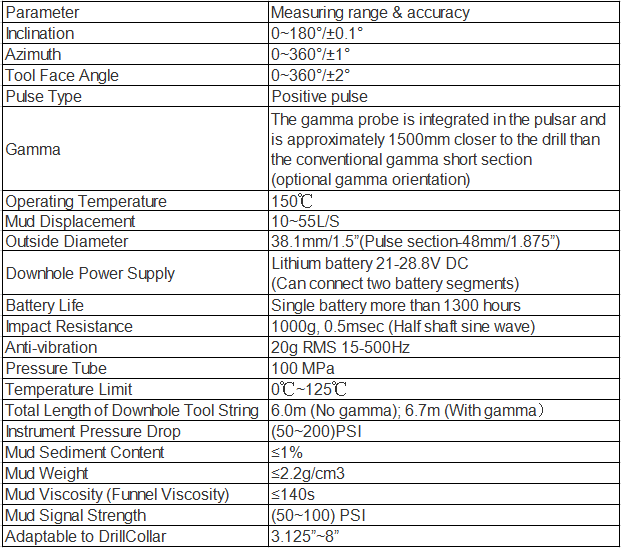

Specifications

Application Techniques

1.Three Signal Transmission Methods of MWD Inclinometer While Drilling

2.Development of MWD for Directional Drilling

3.What Is The Difference Between MWD And LWD?

4.What Is The Principle Of MWD?

5.Possible Problems And Solutions For Shallow Testing Of MWD Instruments

6.MWD Principle Introduction – Cable Transmission Method

More Products