ER-MWD-48 Low Cost Measurement While Drilling (MWD-Φ48mm)

Low Cost Measurement While Drilling (MWD-Φ48mm) system is a new generation of measurement while drilling product developed based on foreign advanced technology and experience and combined with the current domestic application. The products adopt international advanced new materials, new technologies and microelectronics technology to further improve the performance of the instrument. Not only can it overcome harsh working environments such as high temperature, high pressure, vibration, and impact underground, but also has a long service life and high reliability. The MTBF of the instrument reaches 1,000 hours, which effectively improves the efficiency of the instrument, reduces the time required for drilling by instrument failure, and greatly improves economic benefits.

Features

1. The ground equipment is an all-in-one machine structure that integrates the main engine into the driller’s display, eliminating the common 90-meter cable tray and cumbersome cable connection. The data is transmitted wirelessly to the monitor laptop of the directional technician. It can be connected to the Internet for remote operation, so that one engineer can operate multiple Wells.

2. The instrument can be powered by double batteries and can work for more than 600 hours at a time. Improve the use efficiency of the battery, reduce the cost. It also reduces the downhole failure rate of the battery and improves the safety and reliability performance.

3. Downhole instrument adopts soft connection, which simplifies instrument connection steps and shortens field operation time (The average disassembly time is 10 minutes). The real realization of a personal disassembly equipment.

4. The new centralizer uses independent centralizer insert which is low cost, long life and easy to replace and maintain on site.

5. Features of mud pulser :

1). A new sieve cylinder is designed to replace the usual sieve cylinder, compensation outer cylinder and outer cylinder, canceling the flow mode of three sieve screens, so that the structure of the new pulse becomes one.

2). A new grate screen of titanium steel is designed, and the circumferential screen is used to pass the current, which can streamline the external surface of the new pulser, effectively control the generation of mud vortex, improve the mud channel, make the mud flow more reasonable, and reduce the erosion of the instrument by mud. The anti-wear capability is enhanced, the service life is prolonged and the maintenance cost is reduced.

3). The built-in balance piston is designed to replace the commonly used compensation membrane and bellows, and the piston is used for pressure compensation, which improves the reliability of the pulse generator.

4). Extended the maintenance cycle from 600 hours to 800-1000 hours, which is more suitable for deep well operation.

5). Save electricity. A new drive (excitation) and all-electronic drive power supply mode are designed. Eliminate capacitor stub and shorten overall length. Extended battery life from 160 hours to 300 hours per battery.

6). Designed a new valve stem return mechanism, simplified the original spring pull rod mechanism, so that the work of the new pulse more stable.

6. Axial magnetic interference algorithm can effectively solve the influence of axial drilling tool on instrument accuracy and improve the accuracy of data. Especially when the non-magnetic drill collar is short, the accuracy of bearing can be guaranteed.

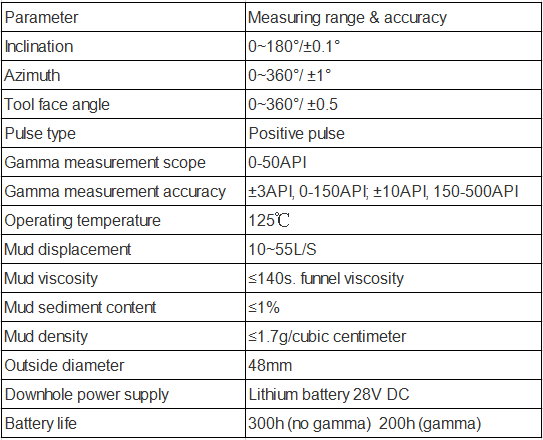

Specifications

Application Techniques

1.Three Signal Transmission Methods of MWD Inclinometer While Drilling

2.Development of MWD for Directional Drilling

3.What Is The Difference Between MWD And LWD?

4.What Is The Principle Of MWD?

5.Possible Problems And Solutions For Shallow Testing Of MWD Instruments

6.MWD Principle Introduction – Cable Transmission Method

More Products