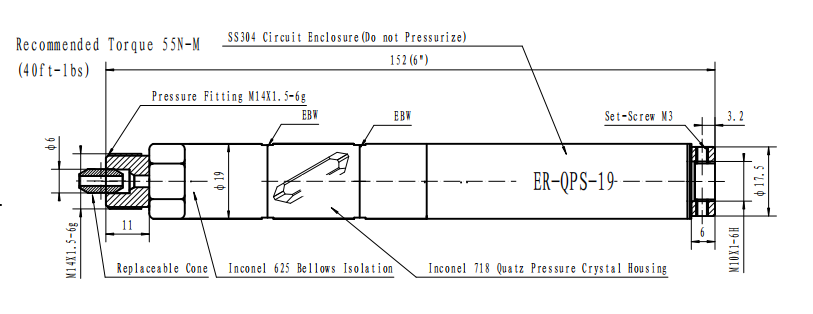

ER-QPS-19 Oil and Gas Quartz Pressure Sensor

Introduction

The current diameter of the sensors is mainly Φ19, the length is different due to the pressure sensor's different models. There are two main structures, one is the sensor's line outer barrel could not withstand the pressure, it needs to be installed in the inside of the downhole instrument, the advantage is facilitating outside bus line of the sensor over the line.

Ericco’s high temperature and high pressure quartz pressure sensors for oil and gas have the characteristics of high reliability and high precision. For decades, the international petroleum industry has always used this quartz crystal pressure gauge as the industry pressure measurement standard. The pressure sensitive element is a quartz resonator, and the output frequency changes with increasing pressure.

The sensitive element maintains the inherent high repeatability and high stability of single crystal quartz. At the same time, there is a temperature probe with a quartz resonator that can directly perform digital temperature compensation on the pressure value. The sensors provide independent pressure frequency signals and temperature frequency signals, and can calculate the temperature-compensated pressure value within the pressure and temperature measurement range. There is no DC signal processing in the sensor circuit, and no DC standard power supply is needed, and the frequency signal is directly output. It can be easily used in memory recording tools and cable recording tools, and the signal output can be adapted to the requirements of any measurement circuit.

Applications

Oil, gas and geothermal well testing

Downhole storage logging tool

Wireline logging and formation tester

Permanent downhole monitoring system

Permanent wellhead monitoring system

Pressure testing while drilling

Specifications

| Item | Recommended application | O.D. |

| ER-QPS-19 | Can be easily used for make up the Φ 25.4, Φ32 multi-parameter production logging tool, well test storage pressure gauge, repeat formation tester, and measurement while drilling. | Φ19 |

The product can be engaged with Logging, Formation Tester, Permanent and Drilling

Recommended Operating Conditions

| Supply Voltage (Vcc) | 3.2-5V |

| Operating Current (Icc) | 2MA (No Load condition with REF) |

| Output Signals | DC Coupled HC CMOS |

| Temperature Range | 150°C/175°C |

| Pressure Range | 70Mpa/100Mpa/140Mpa/160Mpa |

| Weight | 195g |

Application Techniques

1.Three Signal Transmission Methods of MWD Inclinometer While Drilling

2.Development of MWD for Directional Drilling

3.What Is The Difference Between MWD And LWD?

4.Possible Problems And Solutions For Shallow Testing Of MWD Instruments

5.MWD Principle Introduction – Cable Transmission Method

6.What Is The Principle Of MWD?

More Products