1.Application products:

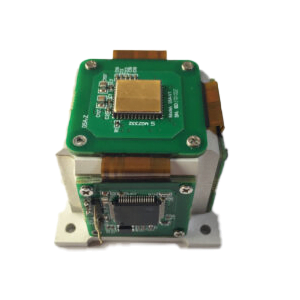

North seeking MEMS Gyro ER-MG2-100

Navigation grade MEMS Gyro ER-MG2-300/400

Tactic grade MEMS Gyro ER-MG-067

2.Temperature data output

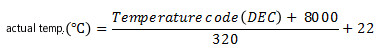

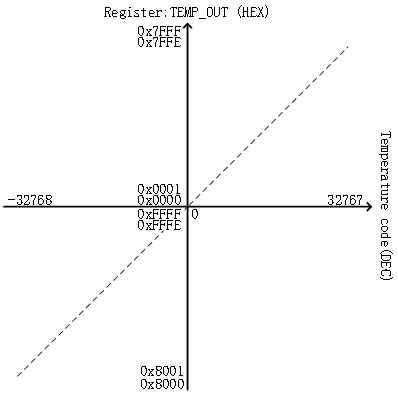

The temperature data is 16 bits wide, in binary complement format, with the highest bit being the symbol bit. Register 0x30 (TEMP_OUT_L) is the temperature sensor output low bytes, and register 0x31 (TEMP_OUT_H) is the temperature sensor output high bytes.

The corresponding relation between the temperature sensor value and the actual temperature can be roughly as follows:

It should be noted that the output signal of the temperature sensor is usually used as a compensation parameter, so only relative accuracy is required. Moreover, the temperature sensor is inside the chip, and the actual temperature is mainly affected by the spontaneous heat of the temperature. Therefore, the output of the temperature sensor has not been accurately corrected. The actual Celsius temperature obtained according to the formula can only be used as a general reference, unable to measure the ambient temperature of the chip's environment.

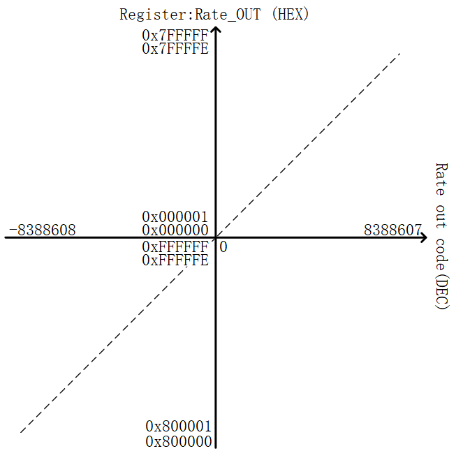

3.Angular velocity data output

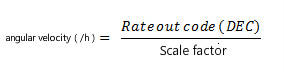

The angular velocity data is 24 bits wide, in binary complement format, with the highest bit being the symbol bit. Register 0x32 (Rate_OUT_L) is angular speed output low bytes, register 0x33(Rate_OUT_M) is angular speed output intermediate bytes, and register 0x34(Rate_OUT_H) is angular speed output high bytes.

The corresponding relation between the value of the angular velocity sensor and the actual angular velocity can be obtained by the following formula:

There is a customization process for the product. In the formula, the calibration factor should refer to the quality inspection report when the product is shipped.

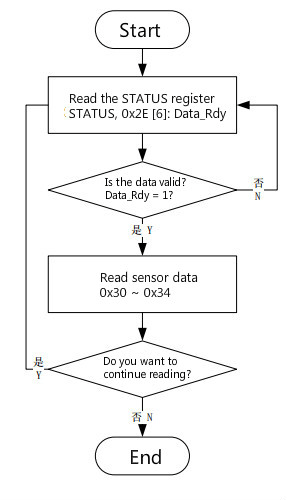

4.Data reading

The output data of MEMS Gyro is stored in 5 register addresses (2 bytes of temperature data, 3 bytes of angular speed data). When the data is updated, the five registers are updated according to the corresponding byte order. In this process, in order to ensure that the register read is the same frame of new data and avoid reading incomplete data, the flag bit (STATUS, 0x2E [6]: Data_Rdy) that determines the validity of the data is needed. When the data in the register is valid, the bit will be set to 1 and kept until all the data in the temperature 0x30~0x34 and angular speed data register are read out, and the flag bit will be cleared to zero automatically.

The recommended process for reading data is to first determine the STATUS, 0x2E[6]:Data_Rdy. Sensor data 0x30~0x34 are read after determining the validity of the data. It should be noted that reading the STATUS register STATUS, 0x2E[6]:Data_Rdy needs to be completed in a separate SPI read process, and cannot be completed in a continuous SPI read operation with the data.

More Technical Questions

1.Feasibility Analysis of MEMS Gyro North Seeking

2.The Calibration Method of High Precision MEMS Gyro

3.The Test of High Performance North Seeking MEMS Gyroscope

4.How to Distinguish MEMS Accelerometer and MEMS Gyroscope Correctly?

5.ER-MG2-100 (0.02°/h) High Precision MEMS Gyroscope

6.Analysis of the main performance parameters of MEMS gyroscope

Products in Article