Single-axis turntable is a special precision equipment developed for the research test, production debugging and maintenance calibration of fiber optic gyroscope and IMU. It is mainly used for speed and position function test. It has the characteristics of stable performance, reliable operation, simple operation, convenient carrying and low purchase cost. The device can also be used for the test of other inertial components and devices.

The main structure of the single axis turntable

Actuate

The rotary table uses hydraulic technology to drive the rack or hydraulic motor, and learns the power development by the way that the rack drives the gear or the hydraulic motor drives the gear. The electric turntable uses servo motor enterprises to provide important power; Therefore, the turntable has air pressure and hydraulic pressure, and we need students to choose according to the different requirements of the CNC management system of our machine tool and the size of the workpiece.

Drive

Common gear drives on the market are rack and pinion drive, worm gear and worm drive and CNC turntable. The turntable not only has worm gear transmission, but also CAM wheel transmission and high-speed direct drive DD motor transmission. The long-life air brake CNC turntable, which is more efficient and wear-resistant, is generally divided by a pair of gears to the motor power transmission worm transmission turntable. The oil brake CNC turntable adopts the transmission structure driven by hydraulic motor. The indexing is carried out by fixed gear meshing against the countertop, driven by a rack driven by a piston.

Brake mechanism

Generally, hydraulic brake equal-division turntable is used to exert a certain pressure on the meshing gear disk to make the end gear disk reliably meshing and positioning. The turntable with arbitrary indexing mostly adopts the way of tightening sleeve or hydraulic or pneumatic brake parts, which has high braking reliability. Single axis turntable adopts large aperture circular hydraulic brake with large clamping area. The disc of the brake mechanism is close to the dial surface of the index plate, and the rigidity is high when it is locked, and it can bear the larger cutting load. The ordinary disc brake clamping area is small, it is difficult to lock the workpiece in the correct position. The distance between the brake disc and the indexing disc is far, resulting in large deflection of the disc surface and low rigidity, which is only suitable for light cutting.

Index positioning

The dividing table generally uses the end tooth disc dividing position, and the dividing position of arbitrary dividing table generally uses the high precision worm and worm dividing position. In general, different types of turntables can be selected according to the accuracy requirements of the workpiece.

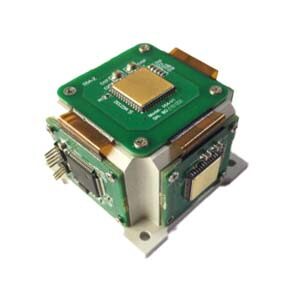

ER-PRT-01 single-axis variable speed turntable includes four types: standard type, high precision type, high speed type and portable type.

The standard type is a mass production product, using high-precision circular induction synchronizer as a feedback component, DC torque motor and PWM driver as the actuator, DSP digital control module as the control core. To provide users with a special slip ring interface, with position, speed, swing and other functions. With mature technology and high reliability, the product has been widely used in the calibration of gyroscopes, accelerometers and other inertial devices. The standard single-axis turntable can be used with an incubator to provide a high or low temperature test environment for the product under test.

The single-axis high-precision turntable adopts the Heidehan encoder imported from Germany as the feedback element, the DC torque motor and the imported linear power amplifier as the actuator, with high position accuracy and rate accuracy, mainly for the high-precision gyroscope and accelerometer test and calibration.

Single-axis high-speed turntable has the characteristics of ultra-high speed range and high speed accuracy. It uses AC brushless motors and AC servo drivers as actuators to provide a test benchmark in the ultra-high speed range for testing and calibration of inertial navigation products such as gyroscopes and MEMS devices.

Compared with the standard model, the portable integrated single-axis turntable integrates the control system in the mechanical body, and the user can control the turntable through the serial port or the touch screen on the body. The turntable is small in size, light in weight, easy to operate and easy to carry, and is suitable for field testing of inertial navigation products and occasions requiring fast maneuvering. The single-axis turntable can also be designed as a horizontal structure to test or calibrate the accelerometer in the range of 0 to ±1g.

Mechanical part

Mechanical indicators are as follows:

1) Surface material: stainless steel;

2) Load capacity: not less than 40Kg;

3) Workbench: φ450mm;

4) End difference :0.02mm;

5) Flatness: 0.02mm;

6) Rotation accuracy :±2;

7) Table magnetic leakage: not more than 5 gauss (10mm away from the table);

8) Range of motion: continuous unlimited;

9) Workbench mounting screw holes :M8 spacing 25mm(gun method, 5 holes ×8 lines evenly distributed);

Control system part

Some indicators of the control system are as follows:

1) Speed range :±0.001 /s~±1000 /s;

2) Maximum angular acceleration :200 /s2

Speed accuracy and smoothness :ω≥10 /s, 3×10-5(average 360);

1 /s≤ω<10 /s, 3×10-4(10 average);

ω<1 /s, 3×10-3(1 average);

3) Angular resolution :0.0001;

4) Angle measurement display mode :0.0001 ~359.9999;

5) Angular position measurement accuracy :±3 ";

6) Measurement repeatability of Angle position :±2 ";

2.3.3 Requirements for the rocking state

1) Swing range :0 ~±45;

2) Swing frequency :0.02HZ~10HZ;

3) Maximum angular acceleration :200 /s2

More Technical Questions

1.Development Trend of Single-axis Turntable in our Country

2.The Internal Structure Characteristics of the Two-axis Turntable

4.Calibration Method of Angular Velocity Sensor for Single-axis Speed Turntable

Products in Article