The fluxgate directional assembly is composed of an accelerometer and a fluxgate sensor. With the increasing number of directional wells and horizontal wells and the improvement of required accuracy, the need to reduce drilling costs at the same time has prompted the emergence of new technologies such as fluxgate directional assembly. The fluxgate directional assembly utilizes the gravity accelerometer and fluxgate to continuously measure the gravity field and magnetic field parameters under the condition of the downhole instrument. Through temperature compensation, numerical calculation and error correction, the inclination angle and azimuth angle of the well are calculated and transmitted to the surface instrument, so as to determine the spatial position of the drilling tool and ensure that the drilling can be accurately extended according to the designed trajectory. Avoid the occurrence of accidents and damage to the underground original public facilities.

As accelerometers and fluxgate sensors are important components, their structures and engineering parameters will be introduced in this paper.

The basic structure and working principle of accelerometer sensor

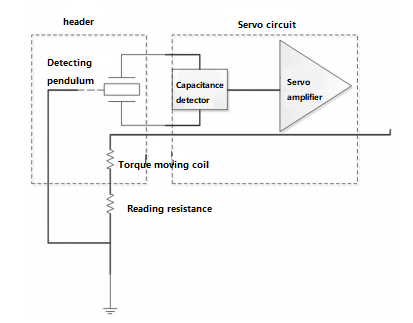

The quartz flexible accelerometer is a pendulum accelerometer. By elastomically connecting its pendulum components on some type of flexible support, the stiffness of the quartz flexible accelerometer in the direction of the input axis is minimal. The quartz flexible accelerometer is composed of a watch head and a servo circuit. The quartz flexible watch head is mainly composed of an integral quartz flexible pendulum assembly, a differential capacitance sensor, a torquer, a shell, etc. The integral quartz flexible pendulum assembly is composed of a center disk, a mounting ring, two flexible flat Bridges connecting the center disk and the mounting ring, and two aluminum frame torque coils fixed on the center disk. The main components of servo circuit are reference triangle wave generator, transconductance compensation amplifier, differential capacitance detector, voltage regulator and current integrator. Figure 1 shows the working principle of a quartz flexible accelerometer.

Figure 1 The working principle of quartz flexible accelerometer

The engineering parameters are obtained by the accelerometer sensor

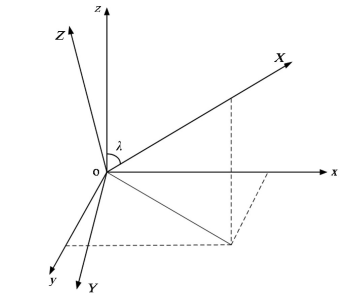

The inclination of the orientation can be expressed by the angle U between the orientation probe and the horizontal plane, but the Angle λ between the vertical plane is often measured, and then the Angle between the vertical plane is determined by the mutual complement (U=90°-λ) (Figure 2), that is, the direction of gravity. Therefore, the inclination of the directional probe can be determined by measuring the actual gravity in the axial direction of the downhole instrument. The relationship between the component G and angle λ measured by the gravity accelerometer and the actual gravitational acceleration g is as follows:

G = g· sinλ

The absolute error of the gravity acceleration signal gradient in the above formula will lead to the calculation error of the inclination, especially when the inclination is close to ±90°, and the small error of the measured value will lead to a great error through the calculation of the above formula. Therefore, the measuring system coordinate system of the three-dimensional orthogonal gravity accelerometer based on the axial direction of the directional probe can be established, and the well inclination can be accurately calculated by the synthesis calculation of the three components Gx, Gy and Gz.

Figure 2 Fluxgate directional assembly axis and measuring system coordinate

(Geodetic coordinates are O-xyz; Measuring coordinate system is O-XYZ)

The three-component synthesis calculation is mainly completed by the three-axis orthogonal measurement data of the three accelerometer sensors. The three orthogonal accelerometers can accurately measure the gravitational acceleration in the three directions, calculate the gravitational acceleration g through the vector synthesis, and convert it to the voltage or current signal output for pairs. Accelerometer output signal u is:

u = k0 + k1 sinα

Formula:

g -- the value of gravitational acceleration;

α - the Angle between the output axis of the accelerometer and the direction of gravity;

k0 - maximum zero offset.

When the scale factor k1 is constant, k0 corresponds to a voltage or current value. The output signal of the accelerometer is proportional to the angle between the output axis and the direction of the accelerometer. According to this principle, three accelerometers are installed along the axis of the instrument in an orthogonal manner, respectively sensing the gravitational acceleration components in three directions, Gx, Gy and Gz.

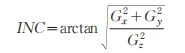

Hole inclination: The angle between the tangential direction line of the hole at any point along the axis and the gravity line passing through that point. In units of degrees. Angle INC formula:

Gravity reference value: is used to measure the accuracy of the data output by the three-way accelerometer sensor standard, the theoretical value is 1. Gravity reference value Gtotal formula:

![]()

The engineering parameters are obtained from the fluxgate sensor

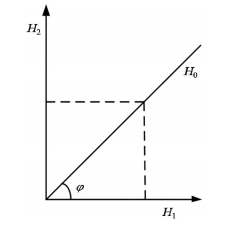

In the last article, we introduced the basic structure and working principle of fluxgate in detail. The earth itself is a large sphere with two magnetic poles N and S, so that the DC magnetic field is generally uniform on the surface of the Earth. At any point on the surface of the Earth, the strength of the magnetic field is decomposed into two horizontal and vertical components. Let the horizontal component of the Earth magnetic field be H0, then the projection of H0 on the two orthogonal probes is H1 and H2, respectively. It can be obtained that φ is the Angle between the North Pole direction of the Earth magnetic field and the orthogonal component H1. When H1 coincides with the sonar reference, φ is the measured azimuth. Figure 3 shows the measurement coordinate system of fluxgate sensor.

Figure 3 Fluxgate sensor measuring coordinate system

Three orthogonal fluxgate sensors obtain three magnetic field components Bx, By and Bz. The output signal of the fluxgate sensor is:

e = kH0H2 msina2ƒt

Formula:

k -- constant, depending on the structural material factor of the sensor;

ƒ - frequency of excitation current;

H0 -- measured magnetic field strength;

Hm - Excitation magnetic field generated by excitation current.

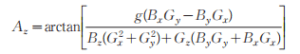

Azimuth Angle: In the plane coordinate system with the previous point as the origin of the borehole trajectory, the north direction line passing through the point is the starting edge, and the projection line on the horizontal plane of the borehole direction line rotating clockwise to the point is the final edge. The angle it turns is called the direction angle of the point, in the unit of degrees.

Azimuth Az formula:

Magnetic reference value: is used to measure the accuracy of the output data of the three-way fluxgate sensor standard, the theoretical value is 55. Magnetic reference value Btotal formula:

![]()

Conclusion

In this paper, the accelerometer and fluxgate, the main sensors in directional assembly are introduced. Fluxgate directional assembly can be divided into wireless and wireline categories, such as the ER-OS-05 is a wireless static measurement fluxgate directional assembly, which operates at 125 ℃. ER-WOS-08 is a wireline fluxgate directional assembly, and its operating temperature can reach 160℃. Similarly, ER-WOS-08H is a high temperature product developed on this basis, and its temperature can reach 180℃, which can be well adapted to the high temperature and harsh environment in oil logging, directional drilling and other fields.

If you are interested in learning more about fluxgate directional assembly, please contact us.

More Technical Questions

1.Fluxgate Directional Assembly: The Working Principle of Fluxgate

2.How Do Fluxgate Directional Assembly work in MWD

3.Application of Fluxgate In Fluxgate Directional Assembly

4.Three Signal Transmission Methods of MWD Inclinometer While Drilling

5.What Is The Difference Between MWD And LWD?

6.What Is The Principle Of MWD?

Products in Article