In the field of MEMS systems, capacitive accelerometers have become a cornerstone technology for inclination or tilt sensing. These devices, essential for various industrial and consumer applications, face significant challenges, especially in dynamic environments where vibration and shock are prevalent. Achieving high precision, such as 0.1° tilt accuracy, requires addressing a range of technical specifications and error factors. This article delves into the key criteria and solutions for effective tilt sensing using MEMS accelerometers.

1.Key Criteria for Accurate Tilt Sensing

Bias Stability: Bias stability refers to the accelerometer's ability to maintain a consistent zero-g offset over time. High bias stability ensures that the sensor readings remain reliable and do not drift, which is crucial for maintaining accuracy in tilt measurements.

- Offset Over Temperature: Temperature variations can cause shifts in the accelerometer's zero-g offset. Minimizing these shifts, known as tempco offset, is essential to maintain accuracy across different operating conditions.

- Low Noise: Noise in sensor readings can significantly affect the accuracy of tilt measurements. Low-noise accelerometers are vital for achieving precise and stable tilt readings, particularly in static environments.

- Repeatability: Repeatability refers to the sensor's ability to produce the same output under identical conditions over multiple trials. High repeatability ensures consistent performance, which is critical for reliable tilt sensing.

- Vibration Rectification: In dynamic environments, vibration can distort tilt data. Effective vibration rectification minimizes the impact of these disturbances, allowing for accurate tilt measurements even when the sensor is subjected to external vibrations.

- Cross-Axis Sensitivity: This parameter measures how much the sensor output is affected by accelerations perpendicular to the measurement axis. Low cross-axis sensitivity is essential to ensure that the accelerometer responds accurately to tilt along the intended axis only.

2.Challenges in Dynamic Environments

Dynamic environments pose significant challenges for MEMS accelerometers in tilt sensing applications. Vibration and shock can introduce errors that corrupt tilt data, leading to significant measurement inaccuracies. For instance, achieving <1° tilt accuracy is extremely challenging in such conditions, while attaining >1° accuracy is more feasible. Understanding the sensor's performance and the application's environmental conditions is crucial to optimizing tilt measurement accuracy.

3.Error Sources and Mitigation Strategies

Several error sources can affect the accuracy of MEMS accelerometers in tilt sensing:

- Zero-g Bias Accuracy and Shift: Zero-g bias errors can arise from soldering, PCB enclosure alignment, and temperature changes. Postassembly calibration can reduce these errors.

- Sensitivity Accuracy and Tempco: Variations in sensitivity due to temperature changes must be minimized to ensure accurate readings.

- Nonlinearity: Nonlinear responses can distort measurements and need to be corrected through calibration.

- Hysteresis and Long-Term Stability: Hysteresis and stability over the sensor's lifetime can impact accuracy. These issues are often addressed through high-quality manufacturing and design practices.

- Humidity and PCB Bending: Environmental factors such as humidity and mechanical stresses from PCB bending can introduce additional errors. In-situ servicing and environmental controls are necessary to mitigate these effects.

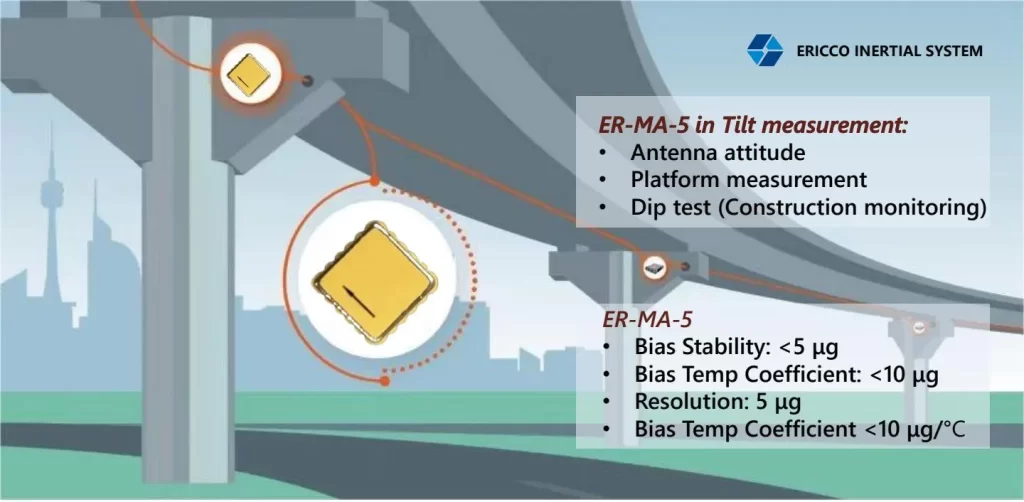

For example, the ER-MA-5 High Accuracy MEMS Accelerometer is tailored specifically for inclination applications. It boasts the bias stability of 5 μg and resolution of 5 μg The factory calibration characterizes the entire sensor signal chain for sensitivity and bias over a specified temperature range (typically −40°C to +80°C), ensuring high precision and reliability upon installation. It is suitable for long-term installation in hydraulic structures such as concrete dams, panel dams, and earth-rock dams, as well as in civil and industrial buildings, roads, bridges, tunnels, roadbeds, and civil engineering foundations. It facilitates the measurement of inclination changes and enables the automated collection of measurement data.

4. Conclusion

MEMS capacitive accelerometers are pivotal in achieving accurate tilt sensing, but they must overcome various challenges, especially in dynamic environments. Key criteria such as bias stability, offset over temperature, low noise, repeatability, vibration rectification, and cross-axis sensitivity play critical roles in ensuring precise measurements. Addressing error sources through calibration and employing integrated solutions like iSensors can significantly enhance the performance and reliability of tilt sensing systems. As technology advances, these sensors will continue to evolve, offering even greater accuracy and robustness for a wide range of applications.

More Technical Questions

1. Full-temperature Performance Optimization Method For MEMS accelerometer

2. A Closed-loop Test Method for Damping Coefficient of Q-Flex Accelerometer

3. Driving Automotive Evolution: MEMS Accelerometers

4. Factors Affecting the Stability of Q-Flex Accelerometers

5. Structure Design of High Precision Quartz Flexible Accelerometer

6. Methods to Maintain the Long-Term Performance of Quartz Flexure Accelerometers