MEMS gyroscope is a kind of MEMS inertial sensor that uses Coriolis effect to be sensitive to the rotational angular rate of objects. It can integrate the sensitive structure and peripheral measurement and control circuit on the same silicon chip. It has the advantages of low cost, small size, light weight and low power consumption, and has broad application prospects in military and civil fields. Since the 1990s, it has been in rapid development and is one of the research hotspots in various countries.

The sensitive structure is the core component of MEMS gyroscope, which is directly related to the performance of the gyroscope such as scale factor, zero bias and anti-vibration. Taking MEMS gyro as the research object, this paper will carry out theoretical analysis on its sensitive structure support system, low order mode, stiffness matrix and quality factor.

Sensitive structural support system

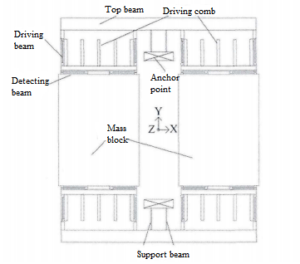

The support system of MEMS gyroscope sensitive structure includes drive beam, detection beam, top beam and support beam, and its schematic diagram is shown in Figure 1. The two mass blocks are connected to the driving comb through the detection beam, the driving comb through the driving beam, the top beam is connected to the support beam, and the support beam is connected to the anchor point, so that the entire movable structure is suspended above the base.

Figure 1 Schematic diagram of the sensitive structural support system

Sensitive structural low order modes

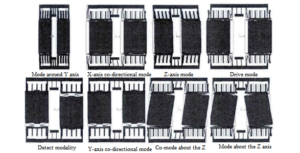

If the mass of the supporting system of the sensitive structure is ignored and the mass block is considered to be rigid, the sensitive structure can be regarded as a multimodal system. The low-order modes of MEMS gyroscope sensitive structure in this paper are: 1) about Y-axis mode, 2) X-axis co-direction mode, 3) Z-axis mode, 4) drive mode, 5) detection mode, 6) Y axis co-direction mode, 7) about Z-axis co-direction mode, and 8) about Z-axis co-direction mode. The schematic diagram is shown in Figure 2.

Figure 2 Schematic diagram of low-order modes of the sensitive structure

Each mode of the sensitive structure directly affects the performance of the gyroscope. The driving mode and detection mode of the sensitive structure directly determine the sensitivity, bandwidth and zero bias stability of the gyroscope. Specifically, first of all, anti-vibration performance is a very important performance index of gyro. Generally, the environmental interference vibration frequency is less than 2000Hz, in order to reduce the influence of the external environment on the gyroscope output, the natural frequency of the first mode of the gyroscope should be greater than 2000Hz. Secondly, the tuning fork gyro uses the opposite vibration of the two mass blocks to offset the common mode error. However, due to the existence of machining errors, the common mode errors will be caused by the same vibration modes. So the X-axis co-mode and Y-axis co-mode are directly related to the common-mode error of the gyro. Finally, the simultaneous and opposite modes around the Z axis are directly related to the orthogonality error of the sensitive structure.

Sensitive structural stiffness matrix

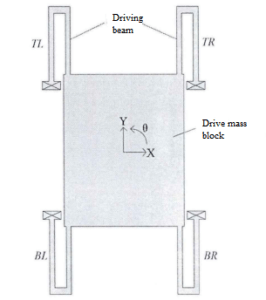

Figure 3 Schematic diagram of the sensitive structure driving motion

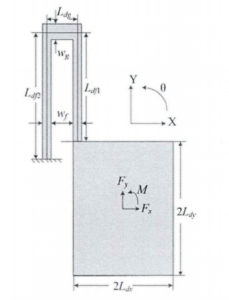

It can be seen from Figure 3 that in the drive mode, the motion of the two mass blocks is symmetric with respect to the Y-axis, and only the drive beam deforms during the motion. Therefore, when only the drive motion is considered, the sensitive structure can be simplified into a simple mass block-drive beam model, as shown in Figure 3. The driving beam is a U-shaped beam, and its structure diagram is shown in Figure 4. Ldf1, Ldf2, Ldg are the length of two long beams and short beams respectively; wf, wg are the width of long beams and short beams respectively; h is the size of the structure thickness direction; the size of the drive mass block in the X and Y axis directions is 2Ldx, 2Ldy respectively. At the same time, the central force acting on the mass block is Fx, Fy and the moment M. Elastic theory is used to solve the stiffness of the driving beam. According to Euler-Bernoulli hypothesis, ignoring the influence of shear force and only considering the effect of bending moment, the bending moment on the driving beam is as follows:

Mdf1=M-Fx(Ldy+x)-FyLdy

Mdg=M-Fx(Ldy+Ldf1)+Fy(Ldx+x)

Mdf2=M-Fx(Ldy+Ldf1-x)+Fy(Ldx+Ldg)

Figure 4 Schematic diagram of structural parameters of the drive beam

Sensitive structural quality factor

1. Energy dissipation mechanism

The quality factor is a parameter that characterizes the damping characteristics, and the amplitude of the detected displacement of the sensitive structure is proportional to the quality factor, so almost all MEMS gyros use vacuum packaging to improve the quality factor. The improvement of quality factor can reduce the damping force and the requirement of driving force amplitude, thus reducing the influence of driving force and damping force on the detection axis. Finally, the in-phase coupling error is reduced and the gyro performance is improved. At the same time, the improvement of the quality factor can stabilize the phase shift of the drive shaft and the detection shaft, which is helpful to the signal extraction and processing of the subsequent circuit.

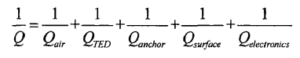

For vacuum-encapsulated MEMS gyros, the energy dissipation is caused by gas damping (Q-1air), thermoelastic damping (Q-1TED), anchor damping (Q-1anchor), surface adsorption damping (Q-1surface), and electrical damping (Q-1electronics). Therefore, the quality factor Q can be written as follows:

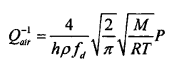

The existing research results show that gas damping and thermoelastic damping are the main energy dissipation modes of sensitive structures under vacuum conditions. The expression of gas damping is as follows:

Where R is the generalized molar constant of the gas, M is the molar mass of the gas, T is the temperature, P is the pressure, ρ is the density of the sensitive structure, and F d is the natural frequency of the driving mode.

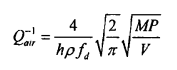

According to the ideal gas equation:

Where V is the volume of gas encapsulated in the sensitive structure, which is a certain value.

The above two formulas can be combined to obtain:

As can be seen from the above equation, gas damping is positively correlated with pressure, so in a high vacuum environment, the influence of gas damping is small, and thermoelastic damping is the main reason for further improving the quality factor of sensitive structures.

2. Vacuum package

Vacuum packaging technology can significantly improve the quality factor of sensitive structures, and is one of the key technologies to improve the performance of MEMS gyroscope. The vacuum packaging form of MEMS gyro mainly includes two categories, device-level vacuum packaging and wafer-level vacuum packaging.

The MEMS gyro sensitive structure introduced in this paper adopts wafer-level vacuum packaging. First, the monocrystalline silicon cover plate is bonded in a vacuum environment by a gold-silicon eutectic bonding process, and the long-term vacuum air tightness of the wafer-type package is achieved by using getter. The vacuum packaged sensitive structure is packaged in the LCC (Leadless Chip Carries) ceramic shell to facilitate the testing of the sensitive structure. The test results show that the quality factor of the MEMS gyro sensitive structure packaged in vacuum at room temperature is in the order of 105.

Conclusion

In this paper, the performance characteristics of MEMS gyroscope are deeply analyzed by analyzing the sensitive structure support system, the low order mode of the sensitive structure, the stiffness matrix and the quality factor of the sensitive structure. As a developer and manufacturer of MEMS gyroscopes, Ericco has a high level of expertise in this field, mainly for navigational and tactical MEMS sensors. The ER-MG2-50/100 is a navigation-grade, high-performance MEMS gyroscope in a sealed ceramic LCC surface mount package with a small size of only 11x11x2mm. It is also capable of operating at a 5V power supply and a wide temperature range (−40°C to +85°C).

I hope you can understand the knowledge of MEMS gyroscope, if you want to learn more content, welcome to click on the related products and articles below.

More Technical Questions

1.Comparative analysis of typical high performance MEMS gyroscopes

2.The impact of turntable error on MEMS gyroscope calibration

3.The analysis of damping in MEMS gyroscope

4.Wafer-level vacuum packaging of MEMS gyroscope chips

5.Noise Analysis and Solutions of MEMS Gyroscope

6.The materials and structure of MEMS gyroscope

Products in Article