North seeker is a kind of inertial measurement and inertial positioning system developed on the basis of inertial navigation system, which can be used in geodetic survey, map drawing, pipeline laying, oil drilling positioning, robot control and other large-scale measurement and accurate positioning. It not only has great potential for development, but also has broad space for development.

With the development of electronic technology, measurement and control technology and computer technology, the safety guarantee system for underground mine operations has been continuously integrated with the above technical fields. Among them, underground physical exploration of coal mines is an important task before mining. That is, when it is predicted in advance where gas may remain, the gas needs to be extracted from the gas layer in advance under the guidance of precise positioning to avoid safety accidents during the mining and excavation process. The traditional hole opening positioning method is the "fixed-point wire pulling method": use the initial coordinate point to draw a line to the exploration drilling position, and determine the mining azimuth angle through trigonometric functions; then determine the pitch angle through the vertical inclination angle measurement of the hole opening operation machine. The working conditions under the mine are harsh, the "fixed-point wire pulling method" is complicated and has low efficiency. At the same time, the highest accuracy index can only reach about 2°, so there is an urgent need to study alternative solutions.

The initial alignment mechanism of the inertial navigation algorithm is a better solution to replace the above problems. However, traditional high-precision azimuth angle solution and attitude maintenance require a combination of high-precision three-axis fiber optic gyroscope or laser gyroscope, which is expensive. According to the application environment and operating mechanism, this paper proposes a low-cost and high-performance three-axis fiber optic gyroscope north seeker, which balances function, performance and cost issues and solves the above problems.

1.Function and implementation

This system mainly consists of four parts: data calculation and control system, motor control and transmission system, fiber optic gyroscope and accelerometer, and north-finding algorithm. The overall plan is: the fiber optic gyroscope and accelerometer are driven by the motor to complete the four-position north-finding work. After improving the accuracy through necessary compensation, the orientation data is transferred to the MEMS-based IMU system for position maintenance and continuous measurement. In a short period of time, the spatial angle calculation of the opening is completed.

2.Sources of North Seeking Error and Control Measures

During the north seeking process, north seeker is mainly affected by the measurement error of the fiber optic gyroscope, the influence of the inclination angle, the influence of the motor control and the position influence. These errors are directly related to the performance of the finished product and the use of the end user, so it needs to be combined with certain theory and engineering. To solve the problem, through analysis below, an engineering solution for the implementation of this plan is proposed.

(1) Performance of fiber optic gyroscope and influence of latitude of measurement point

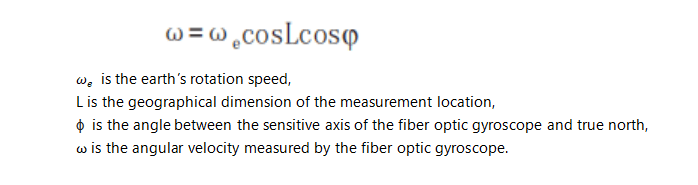

Several performance system characteristics of fiber optic gyroscopes will affect the north seeking accuracy. However, for performance issues, more suitable fiber optic gyroscopes can be selected through screening of indicators. The main discussion below is: the error term caused by different physical input conditions can be corrected through the algorithm after calculation to reduce the impact of the error. The ideal output of the fiber optic gyroscope during the north search process is

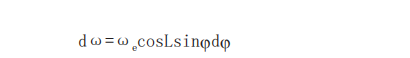

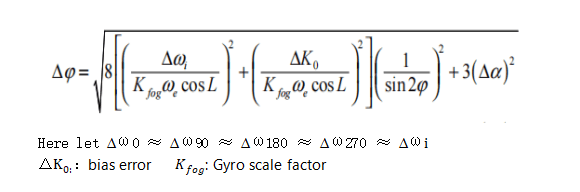

When seeking north, the fiber optic gyroscope distinguishes the difference in orientation by being sensitive to the velocity component of the earth's rotation. By differentiating ϕ under the above conditions, the following equation can be obtained:

thus infer

![]()

It can be seen from the formula that the north-seeking error caused by the measurement error of the fiber optic gyroscope behaves differently at different north-seeking positions. When the sensitive axis direction is 0° or 180°, the output angle of the fiber optic gyro system will be affected; when it is 90° or 270°, it is relatively stable. Therefore, the pre-estimation of azimuth is helpful to improve the north seeking accuracy to some extent. This scheme can effectively improve the north seeking accuracy by using the quadratic north seeking method of predicting Angle and measuring Angle. In addition, combined with certain calibration and compensation measures, the prototype can give the north finding accuracy close to the theoretical level, which undoubtedly increases the design redundancy and improves the yield of the delivered products.

(2)North seeking compensation under tilt angle conditions

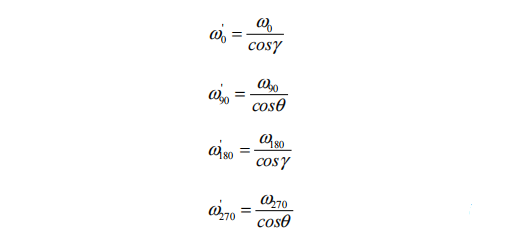

The general north-seeking conditions in underground wells and the rotation plane during gyro transposition are not ideal horizontal planes, and the influence of the inclination of the rotation plane must be considered. Let the inclination angles of the gyro coordinate system relative to the geographical coordinate system be θ and γ. Then under the action of the inclination angle θ and γ, the output of the fiber optic gyroscope at L0, L90, L180, L270 can be recorded as:

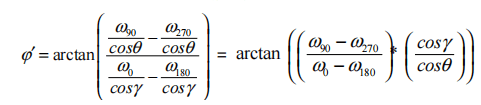

After tilt compensation, the angle between the north-seeking axial position L0 and the north direction ϕ can be converted to:

(3) Motor rotation and other effects

According to the output model of the fiber optic gyroscope, the north-seeking error term at each position can be expressed as :

Combining the formula, it can be concluded that, in addition to the sin2ϕ factor causing the north-seeking error at certain angles, if only the indexing error is considered, the angle output error of the optical fiber north-seeking system is of the same order of magnitude as the turntable indexing error, and Relevant to the number of positions measured by the index. Therefore, the double-cycle north-seeking measure based on four-position north-seeking can theoretically reduce the impact of the turntable position error. In addition, by optimizing the motor control algorithm of the rotating mechanism and adding a photoelectric encoder to the rotating mechanism to strictly control the occurrence of out-of-step, the motor error can be controlled in engineering. A batch of prototypes were produced based on engineering practice, and tests such as north search, attitude static maintenance, and inclination error were completed.

3.Summary

The fiber optic gyro north finder that is currently popular among customers is ER-FNS-03. For details, please refer to the detailed parameters of the product. In addition to fiber optic gyro north seekers, Ericco also follows the trend of technological development and has launched small size north seeker ER-MNS-05 and ER-MNS-06 with MEMS technology as the core. If you are interested, you can take a look.

More Technical Questions

1.Research on orthogonal monitoring technology of north finder

2.Modeling and filtering in signals collected by FOG north seekers

3.Error Modeling and Compensation Analysis of North Finder Based on FFT

4.Research and use of north finder for mining drilling rigs

5.System Analysis of MEMS North Seeker

6.How to Process the Data of FOG North Seeker

Products in Article