Quartz accelerometers have become indispensable in both military and civilian sectors, thanks to their precision in measuring physical parameters such as swing, vibration, and tilt. These sensors have found applications in various fields, including low-frequency vibration calibration, space microgravity measurement, gravity gradient meters, oil drilling, and geological exploration.

In the dynamic realm of aviation technology, characterized by the need for precision and reliability, the integration of quartz accelerometers represents a transformative milestone. Leveraging the exceptional properties of quartz crystal, these accelerometers have reshaped aircraft operations by providing unparalleled accuracy, stability, and durability in challenging aerospace environments. This article delves into the multifaceted impact of quartz flexible accelerometers on aircraft performance and safety, highlighting their crucial role in enhancing operational efficiency and ensuring robust safety measures.

1.Precision Flight Dynamics:

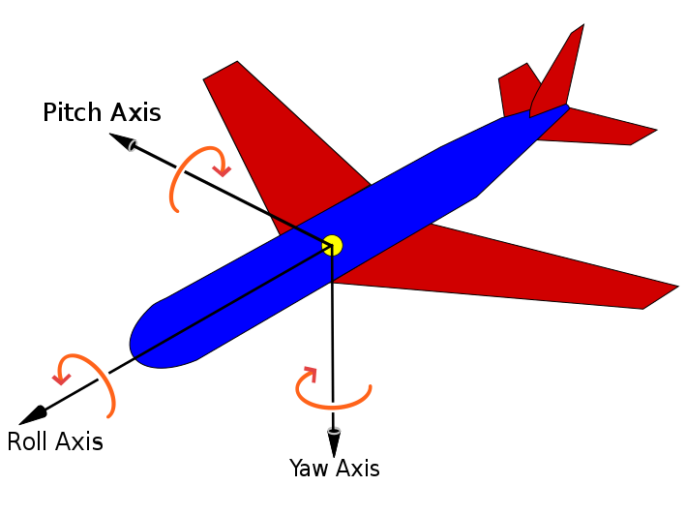

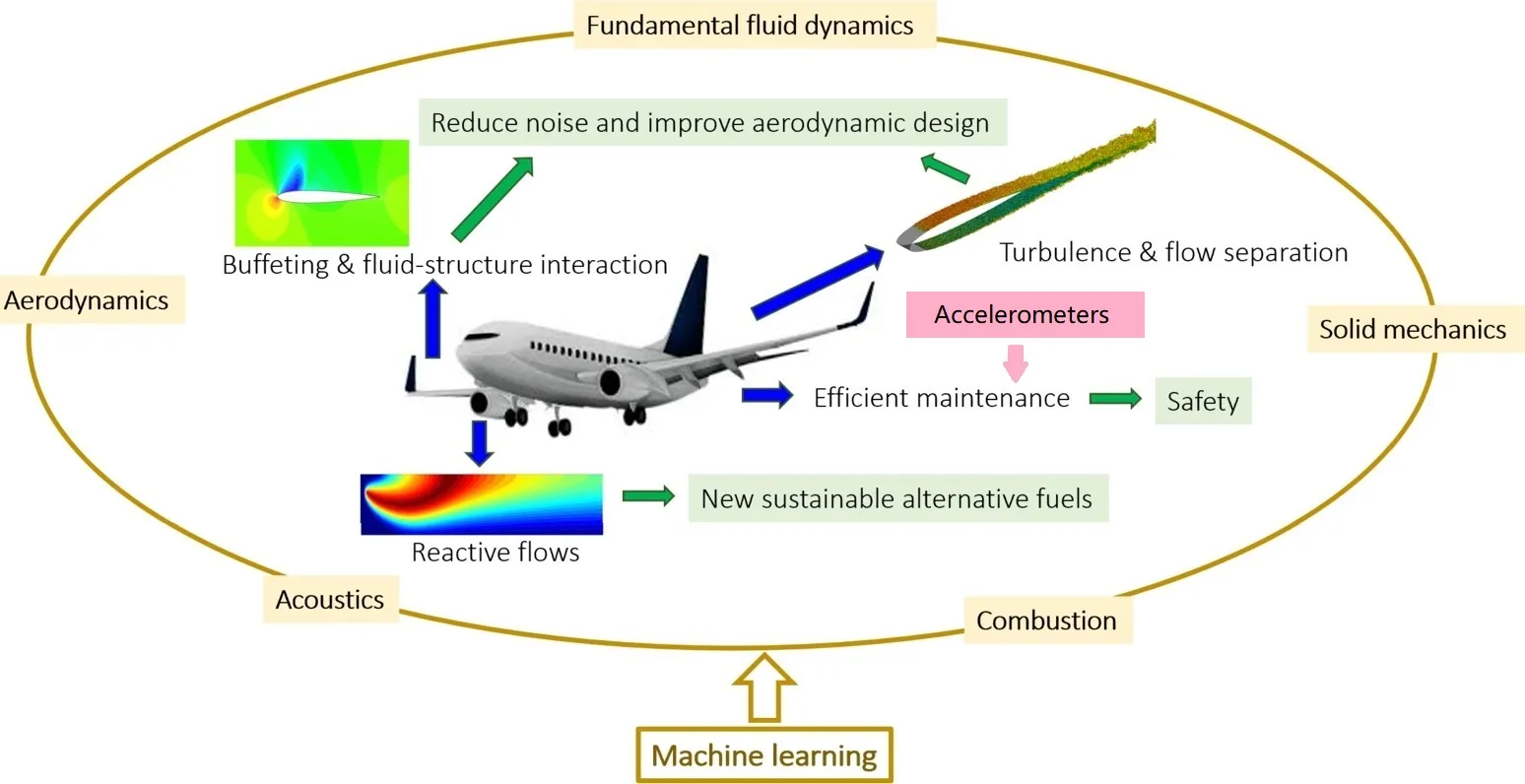

At the core of modern aircraft control systems lies the precision afforded by quartz flexible accelerometers. These sensors, utilizing quartz crystal's inherent stability and sensitivity, enable real-time monitoring and precise adjustment of flight control surfaces. Whether it's maintaining stability during turbulent conditions or executing intricate maneuvers with utmost precision, quartz accelerometers ensure that aircraft respond seamlessly to pilot inputs. This precision in flight dynamics not only enhances safety but also improves passenger comfort, as aircraft navigate with utmost stability and predictability.

2.Enhanced Navigation Capabilities:

Quartz accelerometers have redefined aircraft navigation, offering a solid foundation for reliable and accurate positioning, velocity, and orientation determination. Teamed with advanced gyroscopes and complementary sensors, quartz accelerometers empower aircraft to navigate confidently through diverse environments. Even in GPS-denied areas or adverse weather conditions, these sensors ensure uninterrupted navigation, safeguarding against potential hazards. This enhanced navigation capability not only improves operational efficiency but also enhances overall flight safety by enabling aircraft to reach their destinations reliably and efficiently.

3.Proactive Structural Integrity Monitoring:

Quartz accelerometers play a crucial role in proactive structural health monitoring, transforming aircraft maintenance practices from reactive to proactive. By meticulously capturing and analyzing vibrations and dynamic loads experienced during flight, these sensors enable early detection of potential structural weaknesses or fatigue. Maintenance crews can intervene preemptively, addressing issues before they escalate into safety-critical failures. This proactive approach to structural health monitoring minimizes downtime, extends component lifespan, and upholds the highest standards of aircraft airworthiness and safety.

4.Performance Optimization and Efficiency:

Quartz accelerometers serve as indispensable tools in optimizing aircraft performance and efficiency. By providing precise measurements of acceleration and related parameters, these sensors offer valuable insights into flight dynamics and operational efficiency. Operators can leverage this data to fine-tune flight profiles, optimize fuel consumption, and maximize overall operational efficiency. This optimization not only reduces operational costs but also minimizes environmental impact, contributing to a more sustainable aviation industry.

5.Robust Safety Measures:

Integrated into flight data recording systems, quartz flexure accelerometers bolster aviation safety measures by providing comprehensive insights into aircraft behavior during emergencies or incidents. By capturing crucial acceleration data alongside other critical parameters, these sensors facilitate thorough post-incident analysis, enabling authorities to identify root causes and implement targeted safety measures. This continuous improvement in aviation safety standards ensures that every flight is as secure as it is efficient, instilling confidence in passengers and operators alike.

Summary

The integration of quartz accelerometers represents a paradigm shift in aircraft technology, ushering in a new era of performance optimization and safety enhancement. From precision flight dynamics and enhanced navigation capabilities to proactive structural health monitoring, performance optimization, and robust safety measures, quartz flexible accelerometers are indispensable assets in modern aviation systems. As the aviation industry continues to evolve, driven by innovation and a commitment to excellence, quartz flexure accelerometers stand as beacons of progress, ensuring that aircraft performance and safety reach unprecedented levels of reliability and efficiency.

The ER-QA-03A quartz flexure accelerometer provided by Ericco utilizes premium quartz crystals to deliver highly precise acceleration measurements with exceptional reliability and stability. Its unique flexible design allows it to effectively accommodate high-acceleration applications across diverse environmental conditions, including high temperatures, pressures, and vibrations commonly encountered in aircraft.

The ER-QA-03A quartz accelerometer boasts high resolution, excellent stability, high accuracy, and minimal lag and drift. Especially the ER-QA-03A1 boasts a scale factor temperature coefficient of ≤±20 ppm/℃, bias repeatability of ≤10μg, and scale factor repeatability of ≤15 ppm, making it a core key technology unit for aircraft vibration calibration.

More Technical Questions

1. Mechanism Analysis of Q-Flex Accelerometer Instability

2. 2 Ways to Improve Shock Resistance Performance of Q-Flex Accelerometer

3. Parameters to Evaluate Performance of Quartz Flexure Accelerometers

4. Factors Affecting the Stability of Q-Flex Accelerometers

5. Structure Design of High Precision Quartz Flexible Accelerometer

6. Methods to Maintain the Long-Term Performance of Quartz Flexure Accelerometers