In the realm of modern drilling operations, efficiency reigns supreme. As the oil and gas industry continues to evolve, the demand for enhanced drilling techniques that maximize productivity while minimizing costs has never been greater. Enter Q-Flex accelerometers, revolutionizing drilling efficiency through their seamless integration with a diverse array of sensors.

1.Enhancing Drilling Dynamics with Q-Flex Accelerometers

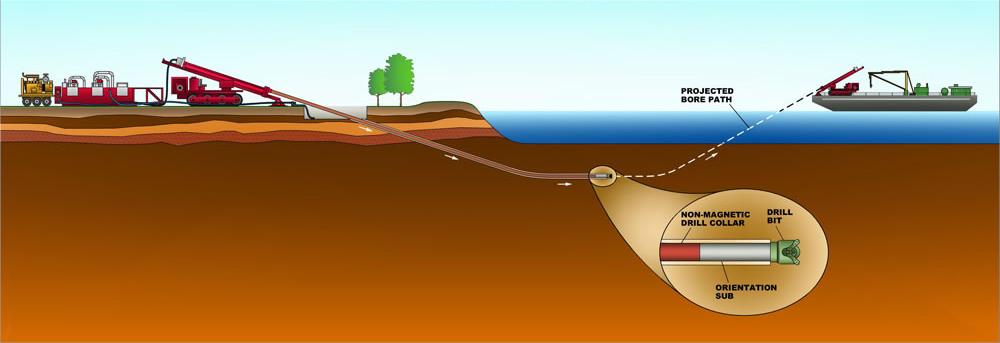

One of the key benefits of combining Q-Flex accelerometers with other sensors is the ability to gain a holistic view of drilling dynamics. By integrating accelerometers with gyroscopes, for instance, operators can track both linear and angular motion with unparalleled accuracy. This comprehensive motion tracking capability enables precise control over drilling parameters, such as toolface orientation and wellbore trajectory, leading to more efficient drilling operations.

Dynamic Drilling Optimization: Accelerometers, when integrated with advanced data analytics and machine learning algorithms, contribute to real-time drilling optimization efforts. By continuously monitoring drilling parameters and analyzing vibration data, these systems identify inefficiencies, predict equipment failures, and recommend adjustments to enhance drilling performance.

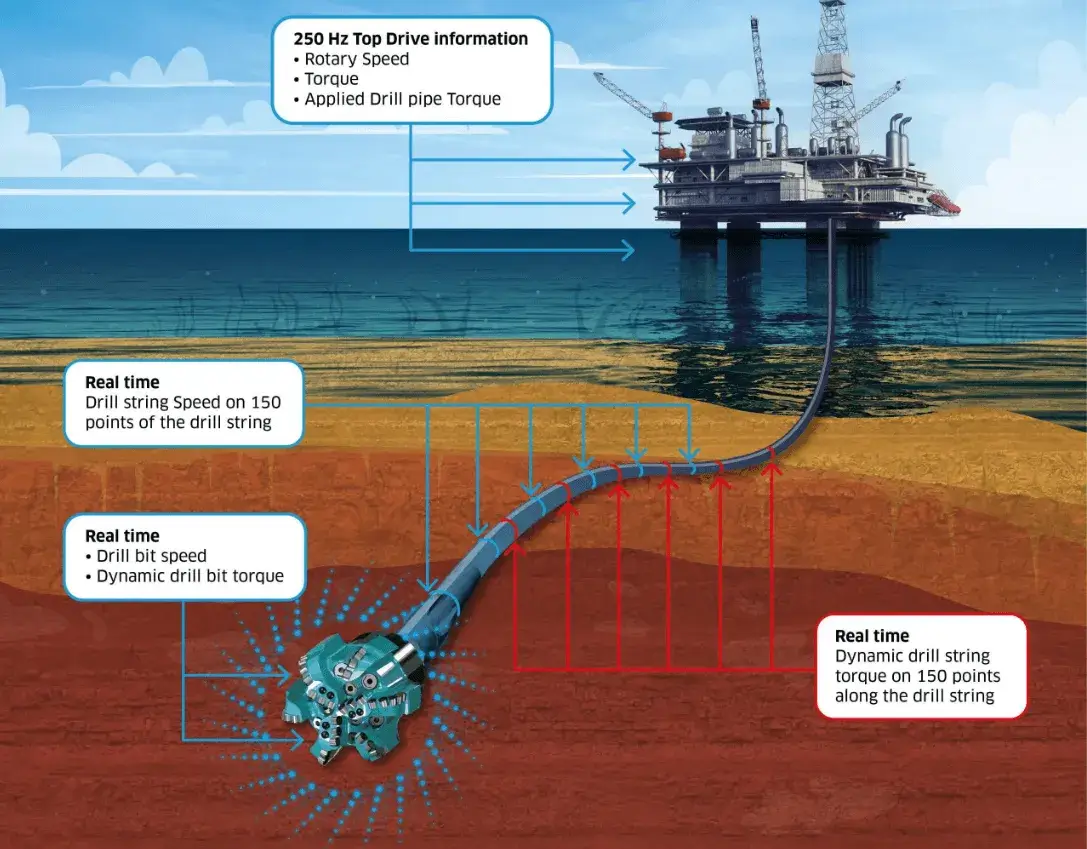

When integrated into drilling control systems, accelerometers provide real-time feedback for regulating parameters such as rotational speed, axial force, and torque. By precisely measuring acceleration and vibration levels, these sensors facilitate adjustments that optimize drilling performance and prevent equipment damage.

Moreover, when Q-Flex accelerometers are paired with pressure sensors, temperature gauges, and flow meters, a wealth of additional information becomes available. This multidimensional data allows operators to monitor drilling fluid properties, detect formation changes in real-time, and optimize mud circulation for improved wellbore stability.

2.Safeguarding Operations: Q-Flex Accelerometers and Sensor Fusion

In addition to optimizing drilling performance, the combined use of Q-Flex accelerometers and other sensors plays a crucial role in enhancing safety. By continuously monitoring drilling parameters and environmental conditions, these sensors can detect anomalies and potential hazards before they escalate into safety incidents. Automatic shutdown systems triggered by sensor data provide an added layer of protection for personnel and equipment alike. They detect abnormal vibrations or shocks, triggering automatic shutdowns or alarms to prevent accidents and ensure personnel safety.

The integration of accelerometers with advanced imaging sensors, such as electromagnetic or acoustic sensors, offers invaluable insights into subsurface geology. By correlating vibration data with imaging data, geologists can accurately map reservoir structures and identify potential drilling hazards, ultimately reducing drilling risks and enhancing well productivity.

3.Specific instrument with Accelerometer-- North Seeker

The North Seeker typically consists of a gyroscope, which measures the rotation of the Earth, and accelerometers, which measure the effects of gravity. By combining data from these sensors with sophisticated algorithms, the North Seeker accurately determines the azimuthal direction of true north, regardless of magnetic interference.

In drilling applications, North Seekers are essential for directional drilling operations, where precise wellbore trajectory control is required. By providing accurate azimuthal information, North Seekers enable operators to steer the drill bit along the desired path, optimizing well placement and maximizing reservoir recovery.

In systems like North Seekers, accelerometers, together with gyroscopes and north-seeking algorithms, play a critical role. They aid in precise motion tracking, enabling accurate determination of the azimuthal direction of true north. This is essential for directional drilling, enhancing survey accuracy, reducing survey time, and improving adaptability to challenging drilling environments.

4.Summary

In conclusion, the synergy between Q-Flex accelerometers and other sensors represents a paradigm shift in drilling efficiency and safety. By harnessing the power of multidimensional data, operators can optimize drilling processes, mitigate risks, and unlock new frontiers in energy exploration and production. As technology continues to advance, the integration of sensors will undoubtedly remain at the forefront of innovation in the quest for greater efficiency and sustainability in drilling operations.

It is notable that Ericco provides high-precision quartz accelerometers, such as the ER-QA-01A3, with a bias stability of 10μg, scale factor repeatability of 10ppm, and a weight of 80g, which can be widely used in aircraft carrier microgravity measurement systems, inertial navigation systems, and static angle measurement systems.

More Technical Questions

1. Dynamic Model of Q-Flex Accelerometer

2. Temperature Compensation Method for Q-Flex Accelerometers

3. Driving Automotive Evolution: MEMS Accelerometers

4. Factors Affecting the Stability of Q-Flex Accelerometers

5. Structure Design of High Precision Quartz Flexible Accelerometer

6. Methods to Maintain the Long-Term Performance of Quartz Flexure Accelerometers