1.Definition of Gyroscope

Gyroscope, a gyroscope device with various functions made by people using the mechanical properties of gyroscope, is widely used in various fields such as science, technology and military. For example: gyrocompass, directional indicator, shell turnover, nutation of the gyroscope, the earth in the sun (moon) torque under the precession.

2.Gyroscope Classification

Today's gyroscopes are mainly Piezoelectric gyroscopes, micromechanical gyroscopes, fiber optic gyroscopes, dynamically-tuned gyroscopes, laser gyroscopes, all electronic, can be combined with accelerometers, reluctance chips, GPS, inertial navigation control systems.

By use:

It can be divided into sensing gyroscope and indicating gyroscope. Sensing gyroscopes are used as horizontal, vertical, pitch, heading and angular velocity sensors in automatic control systems of aircraft motion. Indicating gyroscopes are mainly used to indicate flight status and are used as piloting and piloting instruments.

By function:

Various instruments or devices made of gyroscope's dynamic characteristics mainly include the following:

Gyro directioner

A gyroscopic device that gives an indication of turning Angle and heading of a flying object. Manual adjustment against a precision compass should be made at regular intervals (e.g. 15 minutes).

Gyro compass

A three-degree-of-freedom gyroscope for finding and tracking geographic meridional planes for navigational and flying objects.

Gyro vertical instrument

An instrument that uses pendulum sensors to apply correction torque to a three-degree-of-freedom gyroscope to indicate the vertical line of the ground is also called gyro level. Gyro verticalometer is another kind of vertical indicator or measuring instrument used in aviation and navigation system besides gyro pendulum.

Gyroscopic stabilizer

A gyroscope to stabilize the ship. Once the hull tilts, the small gyroscope precesses along its straight axis, so that the control motor on the main gyroscope frame axis starts in time, and the active torque in the same direction as the original gyroscope torque is applied on the axis, so as to strengthen the precession of the frame and the stability effect of the resulting precession on the hull.

Rate gyroscope

A two-degree of freedom gyro device used to directly determine the angular velocity of a vehicle. Rate gyro and integral gyro are widely used in remote measurement system, automatic control and inertial navigation platform.

Gyro stabilized platform

With gyroscope as the core component, the device that keeps the stabilized object stable relative to the given attitude in inertial space. According to the number of rotating axes that an object can maintain stability, gyrostabilized platforms can be divided into uniaxial, biaxial and triaxial gyrostabilized platforms. Gyro stabilized platform can be used to stabilize instruments and equipment that need accurate orientation, such as measuring instruments, antennas, etc., and has been widely used in aviation and navigation system and fire control, radar universal support.

3.Gyroscope of application

Gyro instrument can not only be used as indicator, but more importantly, it can be used as a sensitive element in automatic control system, which can be used as signal sensor.

According to the need, the gyroscope instrument can provide accurate azimuth, level, position, speed and acceleration signals, so that the pilot or the automatic navigator can control the aircraft, ship or space shuttle and other vehicles to fly according to a certain course.

In the guidance of missile, satellite carrier or space exploration rocket, the signals are directly used to complete the attitude control and orbit control of the vehicle.

Gyroscopic instruments can be used as stabilisers to keep trains on monorail, to reduce the sway of ships in wind and waves, to stabilize cameras mounted on aircraft or satellites relative to the ground, and so on.

As a precision test instrument, gyro instruments can provide accurate bearing datums for surface installations, mine tunnels, underground railroads, oil drilling, and missile silos.

4.How to choose a gyroscope better

The factors we usually consider when choosing a gyroscope are based primarily on minimizing the maximum source of error-in most applications, vibration sensitivity, other parameters that can be easily enhanced by calibrating or averaging multiple sensors, and bias stability error being one of the smaller components of all gyro errors.

When looking at a high performance gyroscope data manual, the first thing most system designers consider is the bias stability specification. After all, this is what describes the bottom line of gyroscope resolution, so it is surely the best predictor of gyroscope performance. However, errors in real gyroscopes due to multiple sources make it impossible for users to take advantage of the high bias stability in the data manual. The only place to get this level of performance is on the lab bench by increasing compensation to minimize the impact of these error sources.

4.1 Environmental factors

All low-and medium-cost MEMS gyroscopes exhibit some zero time zero bias and scale factor errors, as well as some variation with temperature. As a result, users usually temperature compensate them. In general, gyroscopes contain integrated temperature sensors for this purpose only. The absolute accuracy of the temperature sensor is not important for this task. What is important is the repeatability of the temperature sensor and its tight coupling to the actual gyroscope temperature. Modern gyro temperature sensors almost never meet these requirements.

There are many techniques available for temperature compensation (polynomial curve fitting, piecewise linear approximation, etc.). As long as a sufficient number of temperature points are recorded and sufficient care is taken during calibration, the particular technique used is irrelevant. For example, insufficient hold time at each temperature is a common source of error. However, no matter which technique is used or how much care is taken, the limiting factor will be temperature lag - the difference in output through cooling and heating near a particular temperature.

This error can be ignored if the application allows either a reset of zero bias at on-off (that is, on-off occurs without rotation) or a field return to zero with zero bias. Otherwise, this may be a bias stability performance limiter because there is no control over shipping or storage conditions.

4.2 Vibration factor

Ideally, a gyroscope can only measure the rate of rotation and nothing else. In practice, all gyroscopes have some sensitivity to acceleration due to asymmetrical mechanical design and/or imprecise micromachining. In fact, acceleration sensitivity comes in many forms, and its severity varies by design. The most important is for linear acceleration (or g sensitivity) and vibration correction (or g2 sensitivity). Since most gyroscope applications are devices that move and/or rotate in the Earth's 1 g gravitational field, sensitivity to acceleration is usually the largest source of error.

Ultra-low cost gyroscopes typically use extremely simple and compact mechanical system designs that are not optimized for vibration suppression (instead, they are optimized for low cost) and can be greatly affected by vibration. g sensitivity of over 1000°/h/g (or 0.3°/s/g) or higher is not unheard of - more than 10 times worse than one would expect from a high performance gyroscope! There is no point in looking for good bias stability in such a gyroscope, because small rotation of the gyroscope through the Earth's gravitational field leads to large error 2 sensitivity due to g and g. Usually, vibration sensitivity is not specified in these types of gyroscopes - assuming it is very large.

Some designers try to use external accelerometers to compensate for g sensitivity (this is most often done in IMU applications because the necessary accelerometers already exist), which can indeed improve performance in some cases. However, g sensitivity compensation is not entirely successful for a number of reasons. Most gyroscopes tend to have a g sensitivity, which varies with vibration frequency. Figure 2 shows the response of the silicon sensing gyroscope due to vibration. Note that while the gyroscope's g sensitivity is within its rated specification (except for some small spurities at specific frequencies, which may not be significant), it does vary in the 12:1 ratio range from DC to 100 Hz, so calibration cannot be accomplished by simply measuring the g sensitivity at DC. In fact, the compensation scheme will be very complex, requiring sensitivity that varies with frequency.

Another difficulty lies in matching the phase response of the compensating accelerometer to that of the gyroscope. If the phase response of the gyroscope and the compensating accelerometer do not match, the high-frequency vibration error may actually be amplified! Another conclusion is drawn: g sensitivity compensation is only suitable for low frequencies of most gyroscopes.

Vibration correction is usually not specified. Sometimes this is because it is embarrassingly poor or varies from device to device. Sometimes this is simply due to the gyroscope manufacturer's unwillingness to test or specify it (which, to be fair, can be difficult to test). Either way, vibration correction should be of concern because it cannot be compensated with an accelerometer. Unlike the accelerometer response, the gyro output error is corrected.

4.3 A new selection method-vibration sensitivity

Since bias stability is one of the smaller components of the error budget, it is more sensible to select a gyroscope based on its minimization of the maximum error source - in most applications, this would be vibration sensitivity. However, there are times when you may still want lower noise or better bias stability than your chosen gyroscope. Fortunately, there is a solution: average.

Unlike design-driven environmental or vibration errors, the bias stabilization errors of most gyroscopes have noise characteristics. That is, devices are not correlated with each other. Therefore, the bias stability performance can be improved by averaging multiple devices. For every average n devices, you can expect an improvement of √n. Wideband noise can be similarly improved by averaging multiple gyroscopes.

While bias stability has long been considered the "gold standard" specification for gyroscopes, in the real world, vibration sensitivity is often the more serious performance limitation. It is wise to select a gyroscope based on its vibration suppression ability, as other parameters can be easily enhanced by calibrating or averaging multiple sensors.

More Technical Questions

1.Do you know several north seeking schemes used in gyroscopes?

2.How to Differentiate Between Gyroscope Sensors and Accelerometer

3.What is Micro Electro Mechanical Systems Gyroscope

4.Analyze the Working Principle and Application of Three-axis Gyroscope

5.How to Distinguish MEMS Accelerometer and MEMS Gyroscope Correctly?

6.What is the Difference between a Gyroscope sensor and an Acceleration Sensor?

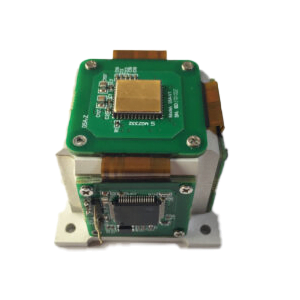

Products in Article