North finding method

To this day, people have been studying north seeking technology. To find north is to determine the direction of true north. Generally there are two methods of non-gyroscopic north finding and gyroscopic north finding. Non-gyroscopic north finding mainly includes magnetic north finding, reference orientation, satellite positioning and so on. Non-gyroscopic north seeking is affected by magnetic field interference, climate and environment restriction, weather disturbance, dependence on satellite and other factors, resulting in low north seeking accuracy and non-autonomous positioning.

Current situation of north-finding gyro

At present, most of the gyroscopes used in underground north finding system at home and abroad are frame gyroscope, fiber optic gyroscope, mechanical gyroscope, dynamic modulation gyroscope, liquid floating velocity integration gyroscope, etc., but these gyroscopes have more or less shortcomings. Frame gyro frame is large, low precision, difficult to compensate, can not work for a long time, rarely used in the field of positioning and navigation; Fiber optic gyroscope is expensive, easy to be affected by the outside world, and difficult to meet the measurement needs in complex underground. The liquid floating velocity integration gyro needs to be prepared for a long time before starting, and is not suitable for working in the well where the temperature is changeable. The dynamic tuned gyro has poor resistance to shock vibration and is not suitable for measurement while drilling. Mechanical gyro has low reliability, limited dynamic range and poor adaptability to environment.

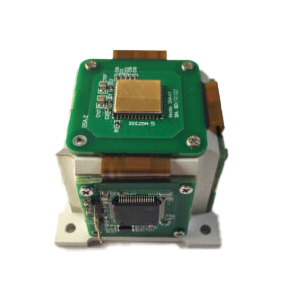

With the development of inertial measurement technology, MEMS gyroscope has been born, which has low cost, small size, low power consumption advantages. At first, MEMS gyroscopes were less accurate and did not match the measurement accuracy of downhole MWD systems. With the development of integrated circuit technology, MEMS inertial sensor has developed rapidly in the field of inertia, and the accuracy of MEMS inertial sensor has been greatly improved. It not only meets the requirements of underground exploration, navigation and aerospace, precision measurement and other fields, but also has a series of advantages that other north finding sensors do not have, such as high reliability and easy mass production. It has gradually become the preferred inertial device in the military field and the civilian field, especially in the field of drilling, for the special conditions of drilling, the need for small size and shock resistance MEMS gyroscope. ER-MG2-50/100 is a north seeking MEMS gyroscope designed for logging tools/gyrotools, mining/drilling equipment, volume 11x11x2mm, such as fingernail size, its bias instability can reach 0.01-0.02°/hr. Angle random walk 0.0025-0.005°/√hr, and can operate at 5V power supply and a wide temperature range (-45 °C to +85°C).

Gyroscopic north finding principle

Gyroscopic north seeking is mainly realized by using gyroscope. Gyroscope can provide attitude information and true north direction of the carrier. The purpose of downhole MWD is to measure the azimuth angle through the downhole north finding system. The magnetic sensor measures the direction of the magnetic north, that is, the magnetic north angle. The gyroscope can measure the angle between the sensitive axis and the true north direction, as well as the angle between the true north direction and the set reference direction. Compared with the fluxgate sensor, the gyroscope has the advantages of high precision, small size, no weather and geomagnetic interference, etc., because it is an instrument that determines the downhole orientation by combining the sensitive earth rotation rate with the measurement scheme and mathematical method. Therefore, during the measurement process of the borehole north finding system, it will not reduce the measurement accuracy and error transmission and accumulation due to the depth of drilling.

Gyroscope is the core sensor in the underground north finding system based on gyroscope. During the underground work, the drilling tool and gyroscope are interfered by high temperature and high pressure, high shock vibration and other factors, which has harsh requirements on the drilling tool and gyroscope. The gyroscope needs to have a small volume diameter to ensure that it can be embedded in the drill tool, and it needs to meet the ability of high temperature resistance and high shock vibration resistance. The ER-MG2-022 is a heat-resistant north seeking MEMS gyroscope for gyrotools that can withstand temperatures up to 125°C and operate in extremely harsh environments where shock and vibration are present.

Gyroscopic north finding is widely used in aerospace, weapon manufacturing, resource exploration, mining and other fields because of its high precision, fast north finding and little influence from external interference.

More Technical Questions

1.Do you know several north seeking schemes used in gyroscopes?

2.The Calibration Method of High Precision MEMS Gyro

3.Feasibility Analysis of MEMS Gyro North Seeking

4.Background and Development Status of MEMS Inertial Sensors

5.What is MEMS Sensor and its Technical Advantages?

Products in Article

.jpg)