MEMS gyroscope is a kind of instrument used to measure and maintain direction, it has a wide range of applications in aviation, aerospace, navigation, seismology and other fields. The precision of MEMS gyroscope is one of the important indexes to measure its performance, which directly affects the use effect and reliability of the gyroscope.

The precision indexes of MEMS gyroscope mainly include zero bias, drift, stability and repeatability. Among them, zero bias refers to the non-zero signal output by the gyroscope in the static state, which will cause the measurement result of the gyroscope to deviate from the true value. Drift refers to the non-zero value number output by the gyroscope in the state of motion, which will cause the measurement results of the gyroscope to change with time. Stability refers to the stability of the performance of the gyroscope in the process of long-term use, which directly affects the reliability and service life of the gyroscope. Repeatability refers to the consistency of the output results when the gyroscope measures the same physical quantity for many times, and it is one of the important indexes to evaluate the measurement accuracy of the gyroscope.

The main performance parameters of MEMS gyroscope

1. Zero bias stability

Zero deviation refers to the output of the gyroscope in the zero input state, which is expressed by the mean value of the output for a long time, which is equivalent to the input angular rate, that is, the degree of dispersion of the observed value around the zero deviation, such as 0.005 degree/sec means that it will drift 0.005 degree per second. Ericco’s ER-MG2-50/100 High Performance North Seeking MEMS Gyroscope zero bias stability can reach 0.1deg/hr, zero bias repeatability is 0.1deg/hr, it can be seen that its measurement accuracy is very high. The long-term steady-state output in the zero-input state is a stationary random process, that is, the steady-state output will ebb and flow around the mean (zero-bias), which is conventionally represented by the mean square error, which is defined as zero-bias stability. The initial zero bias error can be understood as a static error, which does not fluctuate with time and can be calibrated with software.

2. Range (dynamic range)

The range of a gyroscope is usually expressed as the maximum of the positive and negative input angular rates, such as +/-300 degree/sec. The larger the value, the stronger the ability of the gyroscope to be sensitive to the angular rate. In the range of this input angular rate, the nonlinearity of the gyroscope scale factor can meet the specified requirements, and the range of the gyroscope can usually be configured.

3. Sensortivity resolution

Sensitivity (resolution) represents the increment of the minimum input angular rate that can be perceived at a specified input angular rate, for example: 0.05 degree/sec/LSB. In general, the greater the measuring range of a MEMS gyroscope, the sensitivity will decrease accordingly.

4. Scale factor

The scale factor (scaling factor) is the ratio of the gyroscope output to the input angular rate. This ratio is expressed as the slope of a specific line, which is obtained by fitting the input and output data measured over the entire range of input angular rates using the least square method.

5. Degree of nonlinearity

The nonlinearity is the ratio of the maximum deviation of the gyroscope output relative to the line fitted by the least square method in the range of the input angular rate to the maximum output, which represents the deviation degree of the actual input and output data of the gyroscope and determines the reliability of the fitted data.

6. Linear acceleration sensitivity

The linear acceleration sensitivity reflects the gyroscope’s sensitivity to acceleration, and the unit is degree/sec/g.

7. Vibration sensitivity

Vibration sensitivity refers to the sensitivity of the gyroscope to vibration, and the unit is degree/sec/g2. The less sensitive the gyroscope is to linear acceleration and vibration, the better the performance of the gyroscope and the more effective the built algorithm will be.

8. Bias voltage sensitivity

Bias voltage sensitivity refers to the sensitivity of the gyroscope’s output to changes in the power supply, such as: 0.03degree/sec/V, that is, how much the output angular rate changes for every 1V change in the power supply.

9. Bandwidth

Bandwidth refers to the frequency range in which the gyroscope can accurately measure the input angular rate, and the larger the range, the stronger the dynamic response capability of the gyroscope.

10. Self-test function

The self-test function automatically tests the mechanical and CMOS circuit parts of the device before use to provide system robustness.

11. Power consumption

Power consumption includes power consumption when the gyroscope is running at different resolutions or different data output rates, sleep power consumption. This indicator is particularly important in low-power applications such as wearables and Internet of Things applications.

12. Impact survivability

Impact survivability refers to the ability of the gyroscope to withstand acceleration shocks of different degrees, for example, the gyroscope ensures the normal operation of the system after the 2000g acceleration impact. Considering that the application environment of the gyroscope may receive a large impact, this indicator is particularly important, generally the gyroscope is more than its acceleration range will be hung up, must be restarted to work normally.

13. Working temperature range

The mechanical architecture of MEMS gyroscopes determines that temperature will affect the output of data, and exceeding the operating temperature range may cause large deviations in the data output.

14. Packaging error

Package error is the Angle between the diagonal of the bare piece and the diagonal of the package.

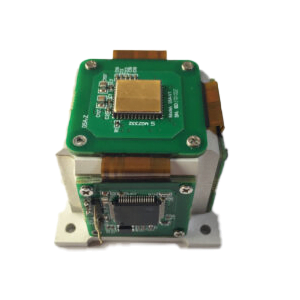

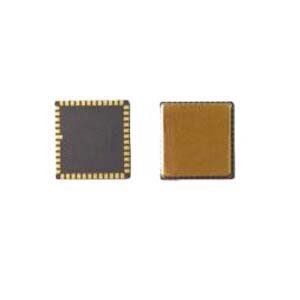

In order to improve the accuracy of MEMS gyroscope, a series of measures need to be taken. First of all, it is necessary to select high-quality gyroscope devices to ensure that their manufacturing process and quality meet the requirements. Secondly, it is necessary to carry out accurate calibration and debugging to eliminate errors such as zero bias and drift. In addition, it is also necessary to adopt a suitable installation method and use environment to avoid external interference and influence. The ER-MG2-50/100 is a single-axis MEMS angular rate north seeking sensor (gyroscope) designed as an advanced differential sensor that rejects the effects of linear acceleration, enabling the ER-MG2-50/100 to operate in extremely harsh environments where shock and vibration are present. This high-precision north finder is designed for north finding, pointing, and initial alignment in logging/gyroscopes, mining/drilling equipment, weapon/UAV launch systems, satellite antennas, target tracking systems, etc.

Finally, regular maintenance and overhaul should be carried out to ensure that the performance of the gyroscope is stable and reliable.

More Technical Questions

1.Where are MEMS Gyroscopes Used?

3.What is the Hardware Interface of Ericco MEMS Gyro

4.How to Configure the Register of Ericco MEMS Gyro

5.What Data Format is High Performance MEMS Gyro

6.How to Weld and Install High Performance MEMS Gyro

Products in Article