At present, tilt sensors are widely used in construction machinery, road machinery, port machinery, lifting machinery and other construction machinery fields, which can realize real-time monitoring and control of angle-related state and attitude in the operation process of construction machinery. However, the inclinometer sensor often has defects such as nonlinear error and temperature drift error in practical application, so that the accuracy is easily affected and the measurement error is too large, which can not meet the requirements of practical application of construction machinery equipment. In addition, in the mass production process of the tilt gauge, it is easy to have the acceleration sensor installed tilt, so that the measurement angle is offset. Therefore, in order to improve the measurement accuracy of the inclinometer sensor, the product needs to be calibrated, temperature drift compensation and accuracy detection before leaving the factory to ensure that the product meets the factory standard.

1.Inclination sensordetection system

The high-precision inclinometer sensor detection system CAN intelligently control the temperature change of the thermostat, the position rotation of the servo motor and the CAN communication control with the tilt gauge. The test data can be displayed and controlled in real time through the interface designed by Labview software. The angle sensor can automate 0° angle calibration, temperature scale aging, angle linear calibration and angle error detection.

2.Inclinometer sensordetection system function

2.1 0° angle calibration function

The tilt measurement sensor detection system uses smooth marble as the cornerstone, which is not easy to shake or deform, and the plane is adjusted to the standard 0° plane by the measuring instrument. When the tilt gauge is located at 0° water level, the system controller SYMC sends 0° calibration instructions to correct the original 0° data.

2.2 Temperature bleaching aging function

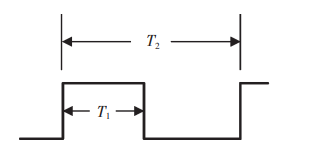

The purpose of temperature drift aging test is to solve the problem that the performance of tilt sensor components is unstable with temperature changes. The specific reason is that the output of tilt sensor and speed sensor is PWM signal, and the waveform is shown in Figure 1.

Figure 1 PMW signal of acceleration sensor

The formula for calculating the output acceleration of the inclination sensor is a = (T1 /T2-0g output)/sensitivity

The output angle of tilt gauge is calculated by θ=sin-1 (a).

In the formula, 0g output and sensitivity are constants in theory, but in fact, they will change due to temperature changes in component performance. To realize temperature drift compensation correction for 0g output and sensitivity values of the tilt measurement sensor, the detection system needs to sample at least 3 typical temperature points (such as -30 ℃, 25 ℃, 60 ℃) under 0g output values and sensitivity values. The output values of the acceleration sensor at 0°, 90°, 180° and 270° were collected at each temperature point, and the output values of the acceleration sensor at other temperatures and positions were linearly corrected by piecewise linear compensation method, so as to calculate the 0g output and sensitivity values of the tilt gauge at different temperatures.

2.3 Angular linear calibration function

The inclinometer sensor adopts linear fitting linearization measures to make the input and output signals have a linear relationship. The specific algorithm adopts two-stage quantization method, such as: take 24° and 26°, and use a straight line connection to replace the original curve; 26 degrees and 28 degrees are also connected by a straight line. The piecewise linear fitting method is adopted for the whole 360°, so that the relationship between the measured data and the actual angle is close to linear relationship. In the algorithm, the more test angle points collected, the more the curve calculated by the algorithm approximates the linear relationship. The inclinometer sensor detection system can randomly select 120 angle sample points, start from 0° angle, every 3° interval, respectively, to carry out piecewise linear fitting of the tested inclination sensor, angle calibration, and maximize the nonlinear error of the inclination sensor.

2.4 Angle detection function

The angle detection system can compare the angle value measured by the inclination sensor with the corresponding angle value detected by the encoder in the detection system, so as to calculate the measurement error of each angle position of the tilt gauge. angle detection selects 60 test sample points, and the selected angle is between the selected point of calibration angle, so as to effectively detect the accuracy of linear fitting algorithm of tilt measurement sensor. The angle resolution of the inclinometer sensor product is ±0.1°, and the accuracy of the angle encoder selected by the detection system is ±0.003°, which can make the detection error resolution reach the thousandth grade, effectively ensuring the accuracy of the system angle detection.

3.Check system test requirements

The requirements of the high-precision inclination sensor detection system in the test: ① The ambient temperature in the thermostatic box should be constant, and the change is less than 0.5 ℃; ② Ensure that the positioning of the structure shaft is consistent with the position of the sensor on the turntable, and the deviation of the angle position of 0°, 90°, 180°, 270° is less than 0.1°; ③ Ensure that the turntable will not shake when rotating, and the sensor can be firmly installed on the turntable; ④ Ensure that the support components can be adjusted in height and match the size of the thermostat; The whole device should have sufficient stiffness and will not be deformed in high and low temperature environments.

4.Check the system test results

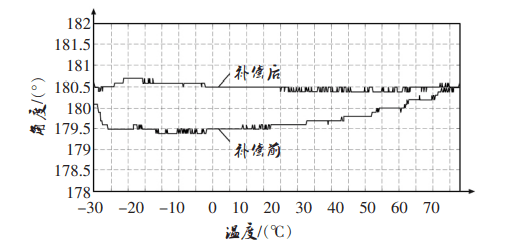

The high precision tilt sensor detection system can test 96 board tilt sensors at a time, and the entire test cycle is 6 hours. After the 0° calibration is completed, the system conducts temperature drift aging test. Figure 2 shows the temperature drift effect data of the single-board tilt sensor at 180.5° from -30 ℃ to 80 ℃. It can be seen that the temperature drift compensation front and rear tilt sensor has obvious temperature drift performance effects.

Figure 2 Data Curve of Temperature Coefficient

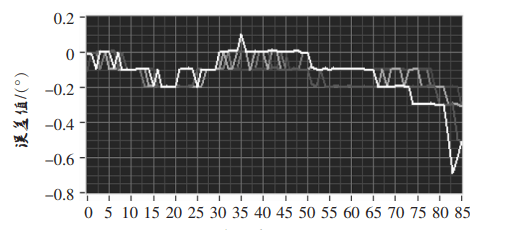

After the temperature bleaching, the system calibrates 120 test angles of the inclination sensor, and the angular resolution of the inclination sensor is ±0.1°. After the calibration of the inclinometer sensor is correct, the detection system randomly selects 60 angles within 360° (which do not coincide with the angle selected by the calibration), and calculates the measurement angle of the tilt measurement sensor and the feedback angle error of the system encoder. The angle error curve formed by the deviation between the measurement angle of the inclination sensor and the feedback angle of the system encoder is shown in Figure 3.

Figure 3 Error curve of angles

After the test is completed, it can be identified from the figure that the angle error of the white curve is greater than -0.3°, which is a unqualified product and needs to be returned to the factory for processing.

Conclusion: The measurement accuracy of tilt sensor can be greatly improved by calibrating, temperature drift compensation and accuracy detection. Ericco's ER-TS-3160VO (accuracy 0.01°) and ER-TS-12200-Modbus (0.001°) have been calibrated at 0° angle, temperature drift aging function test, angle linear calibration and angle detection before leaving the factory, so their accuracy is not easily affected, resulting in excessive measurement errors.

The application of high precision inclination sensor detection system realizes intelligent testing instead of manual testing. Production practice has proved that the test cycle of the tilt gauge is reduced from the original 9 h to 6 h, and the unmanned test can still be carried out at night, to achieve two batches of test a day, and the number of test pieces per cycle is increased from the original 60 pieces to 96 pieces, which greatly saves labor costs and improves production efficiency and product quality.

More Technical Questions

1.What are the Advantages of Tilt Sensor

2.Is Tilt Sensor Analog or Digital?

3.Is a Tilt Sensor the Same as as an Accelerometer?

4.What can a Tilt Sensor be Used for?

5.What are the Three Types of Tilt Sensor?

Products in Article