MEMS inertial devices, primarily referring to gyroscopes and accelerometers, are the most crucial sensors in MEMS INS, used to obtain full attitude information for navigation calculations. Over many years, inertial navigation mechanical arrangement algorithms have matured. The attitude, speed, and position update algorithms included in the INS system typically induce errors that do not exceed 5%. The majority of the remaining errors stem from inertial device errors, installation errors, initial condition errors, and motion disturbances.

Inertial device errors are a critical factor determining the accuracy and stability of an INS system. These errors are primarily composed of deterministic errors and random errors. Deterministic errors in inertial devices can be treated as system errors and are calibrated and compensated for before practical use. Random errors are indeterminate and, particularly for MEMS inertial devices, tend to be unstable and full of uncertainties, necessitating targeted research and modeling.

Since research on the calibration and compensation of deterministic errors in inertial devices is well-developed, achieving the required precision and effectiveness with various methods, this paper will not delve into it further. Instead, it will focus on the analysis of deterministic errors and analysis of random for MEMS INS.

Analysis of Deterministic Errors in MEMS INS

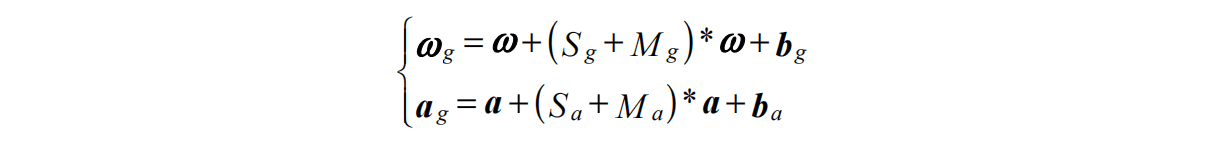

Deterministic errors in inertial devices can be summarized as zero bias, scale factor, and the inherent cross-coupling errors of the inertial devices. Additionally, MEMS inertial devices are sensitive to changes in environmental temperature, with significant zero bias fluctuations. Moreover, acceleration introduces measurement errors in almost all MEMS gyroscopes, known as g-sensitive errors. The deterministic error model of inertial devices can be expressed as follows:

Analysis of Random Errors in MEMS INS

In addition to deterministic errors, inertial devices exhibit a significant number of random errors. Compared to deterministic errors, random errors in inertial devices are more complex, varying unpredictably over time and involving more parameters. Typically, the industry establishes a time series model for the random errors of inertial devices and then uses filters to process the model's residuals, thereby mitigating the impact of random errors on inertial measurements and calculations.

Generally, the main types of random errors in inertial devices include:

- Quantization Noise (QN): This noise results from the quantization and digital nature of the gyroscope's output, representing the gyroscope's minimum resolution. Quantization noise has a short cross-correlation time and increases with sampling speed.

- Angular Random Walk (ARW): Caused by integrating broadband angle rate white noise, resulting in a total angle increment error with random walk characteristics and angle rate errors with white noise characteristics.

- Rate Random Walk (RRW): Caused by integrating broadband angle acceleration white noise, leading to angle rate errors with random walk characteristics and angle acceleration errors with white noise characteristics. Main factors include mechanical vibrations, frequency instability of excitation signals, shot noise, and high-frequency noise with short correlation time.

- Bias Instability (BI): Results from low-frequency zero bias fluctuations in angle rate measurements, with power spectral density inversely proportional to frequency, also known as 1/f noise.

- Rate Ramp (RR): When MEMS gyroscopes operate for extended periods, their measurements exhibit a slight monotonic trend, referred to as rate ramp, which can be classified as deterministic error. Temperature changes and prolonged slight acceleration in the same direction are major sources of this error.

The characteristics of these random error parameters are summarized in the table.

| Name | Parameter Symbols | Allan variance | Power Spectral Density |

| Quantization noise | Q | 3Q2/τ2 | (2πf)2τQ2 |

| Angle random walk | N | N2/τ | N2 |

| Angular rate random walk | K | K2/(2πf)2 | K2 τ/3 |

| Bias stability | B | 2B2ln 2 /π | B2/(2πf) |

| Rate ramp | R | R2 τ2/2 | R2/(2πf)3 |

Solution

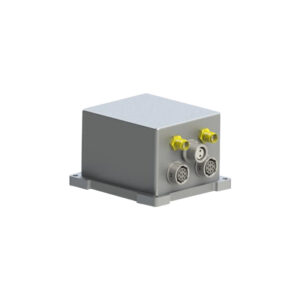

Ericco is at the forefront of inertial navigation technology and has recently introduced three GNSS-aided MEMS INS products with varying levels of accuracy (mapping level, tactical level, and industrial level). Notably, the mapping level MEMS INS ER-GNSS/MINS-01 features a 0.02°/hr bias instability and a 0.005°/√hr angular random walk, along with a high-precision MEMS accelerometer with a large range (±60g, zero bias instability <2μg).

More importantly, in an integrated navigation system, the INS leverages its high short-term accuracy to provide GNSS with continuous and comprehensive navigation information. Conversely, GNSS helps estimate INS error parameters, such as bias, resulting in more precise observations and reduced INS drift. GNSS offers stable long-term accuracy, provides initial values for position and speed, and corrects accumulated errors in the MEMS INS through filtering. The ER-GNSS/MINS-01 stands out as an excellent solution.

More Technical Questions

1. What Is GNSS-aided MEMS INS and How Does It Work?

2. How to Improve the Performance of MEMS Inertial Navigation Systems?

3. Full-temperature Performance Optimization Method For MEMS accelerometer

4. Classification And Performance Improvement Of MEMS Gyroscope

5. MEMS Accelerometer Packaging Technology

6. Performance Analysis of GNSS RTK Timing