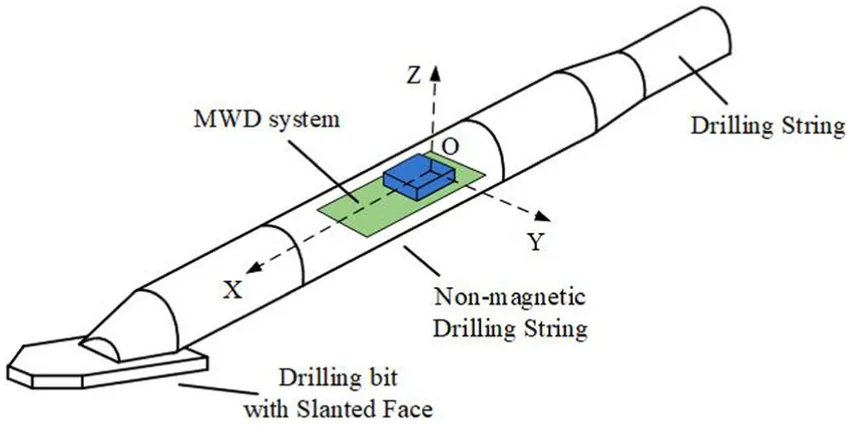

During the drilling process, directional drilling tools play a crucial role in controlling the trajectory of the wellbore in real-time to reach target formations. Real-time measurement of downhole tool attitude parameters is essential for implementing effective measures based on the measurement results, thereby enhancing the adaptability of the drilling system. This ensures better wellbore quality, reduces underground risks, and lowers development costs.

However, factors such as tool rotation, vibrations near the drill bit, and harsh downhole conditions can significantly affect the accuracy of tool attitude parameters measurement. This article proposes to research and design a dynamic attitude measurement device based on Q-Flex accelerometer to eliminate or mitigate errors during tool attitude dynamic measurement processes and accurately measure parameters such as inclination angles and tool face angles.

1.Introduction to Drilling Tools Attitude and Errors

During the real-time measurement of drilling tools attitude parameters, the rotational motion of the tool and vibrations near the drill bit can greatly affect the measurement accuracy of tool attitude parameters. Therefore, it is necessary to analyze the impact of tool rotation and vibrations near the drill bit on the output signals of accelerometers to establish a theoretical basis for eliminating their influence on attitude measurement.

On one hand, the centrifugal acceleration generated by tool rotation distorts the tool attitude measurement signal and increases angular measurement errors. On the other hand, vibrations near the drill bit result in significant amplitude and high-frequency vibration signals, leading to substantial influences on the tool attitude measurement system and consequently increasing measurement errors.

2.Basic Solutions for Drilling Tools Attitude Errors

To address these two primary influencing factors, this study proposes to research and design a dynamic attitude measurement device to eliminate or mitigate errors during tool attitude dynamic measurement processes and accurately measure parameters such as inclination angles and tool face angles. The main solutions and research contents for this issue are as follows:

For the dynamic measurement problem of drilling tools attitude under rotation and vibration conditions, first, analyze both static and dynamic aspects of tool attitude parameter measurement. Simulate downhole vibration environments using an indoor vibration table to test the characteristics of q-flex accelerometer. Conduct spectrum analysis on the test results and propose a measurement scheme combining q-flex accelerometer and gyroscopes to compensate for rotation using gyroscopes, solve the calculation error problem caused by rotation, and address dynamic measurement issues caused by vibration using accelerometer signal processing methods.

(1) To address the problem of measurement signal distortion caused by centrifugal acceleration generated by drill rotation, research the relationship between attitude parameter measurement errors and the centrifugal acceleration of directional drilling tools. Compensate for rotation to weaken the impact of tool rotation on attitude parameter measurement.

(2) Regarding the issue of vibrations near the drill bit affecting drilling tools attitude parameter measurement, first consider mechanical damping for accelerometers. Study the characteristics of quartz flexible accelerometers by simulating downhole vibration environments on a vibration table, altering vibration parameters, recording accelerometer output signals using an oscilloscope, conducting spectrum analysis on the output signals of quartz flexible accelerometers, and analyzing the relationship between accelerometer output signals and vibration. Consider mechanical damping for quartz flexible accelerometers, analyze the characteristics of accelerometers after mechanical damping, compare them with the characteristics before damping, and observe whether damping measures are effective.

(3) Based on the analysis of quartz flexible accelerometer characteristics, propose a vibration signal processing method to process accelerometer output signals, considering a combination of hardware and software. Use signal processing modules in circuit design and signal processing algorithms in software.

(4) Based on accelerometer attitude measurement principles, design a scheme for the combination measurement system of q-flex accelerometer and gyroscopes. Fabricate a dynamic attitude measurement device, design and debug its software and hardware, and perform performance tests on the dynamic attitude measurement device using an analog vibration table.

3.Conclusion

Ericco provides high-precision quartz accelerometers, such as the ER-QA-03D, with small errors and high accuracy. Its bias stability is 10 mg, scale factor repeatability is 80 ppm, and weight is 65g. It boasts operating temperature of -55~180℃. The products are widely used for aerospace inertial navigation, guidance and control, industrial measurement and for measurement-while-drilling (MWD) in oil and gas fields. The problem of azimuth orientation in MWD technology is particularly prominent. The high temperature environment, accompanied by strong vibration shock, is a difficult problem to overcome in MWD.

More Technical Questions

1. Optimizing Drilling Efficiency: Q-Flex Accelerometers Combined with Other Sensors

2. Temperature Compensation Method for Q-Flex Accelerometers

3. Driving Automotive Evolution: MEMS Accelerometers

4. Factors Affecting the Stability of Q-Flex Accelerometers

5. Structure Design of High Precision Quartz Flexible Accelerometer

6. Methods to Maintain the Long-Term Performance of Quartz Flexure Accelerometers