The automotive industry is witnessing rapid technological advancements aimed at enhancing vehicle safety, performance, and user experience. Among the key innovations driving this progress are MEMS accelerometers—miniature sensors capable of measuring acceleration with remarkable precision and reliability. This paper aims to provide a detailed examination of the application of MEMS accelerometers in various automotive systems, highlighting their significance and impact on vehicle dynamics and safety.

1. Principles of MEMS Accelerometers:

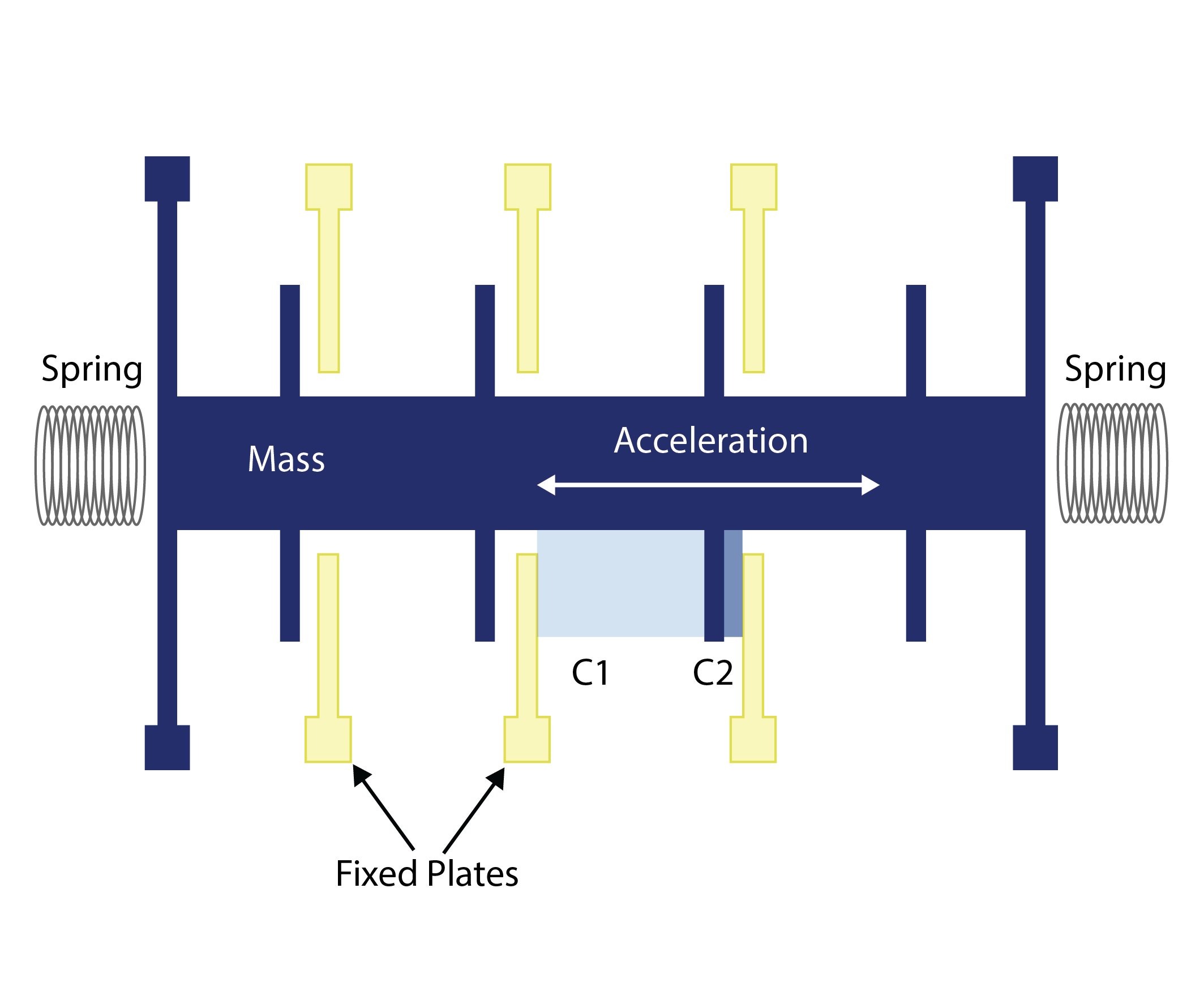

MEMS accelerometers operate on the principle of detecting changes in capacitance, piezoelectricity, or piezoresistivity in response to acceleration forces. These sensors consist of microscopic silicon structures suspended within a microchip, allowing for accurate measurement of both static and dynamic acceleration. The fundamental design and operating principles of the accelerometers make them well-suited for integration into automotive applications, where reliability and precision are paramount.

Fig.1 Simple Model of MEMS Accelerometer

2. Applications in Vehicle Dynamics:

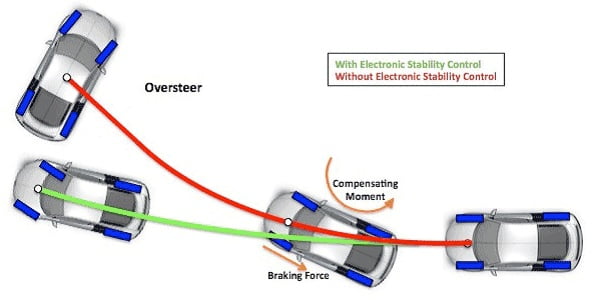

MEMS accelerometer plays a crucial role in enhancing vehicle dynamics by providing real-time data on acceleration, deceleration, and lateral forces. These sensors are integrated into electronic stability control (ESC) systems, traction control systems (TCS), and anti-lock braking systems (ABS), enabling precise modulation of braking and throttle inputs to optimize vehicle stability and traction under varying driving conditions. Additionally, the sensor contribute to active suspension systems, enabling adaptive damping control and improving ride comfort and handling characteristics.

3. Impact on Vehicle Manufacturing and Design:

The integration of MEMS accelerometers in automotive systems has significant implications for vehicle manufacturing and design. These sensors enable the development of lighter, more compact electronic control units (ECUs) and sensor modules, contributing to overall vehicle weight reduction and improved fuel efficiency. Additionally, MEMS accelerometer facilitates the implementation of predictive maintenance systems, enabling proactive monitoring of vehicle components and subsystems to prevent potential failures and optimize maintenance schedules.

4. Safety Systems Integration:

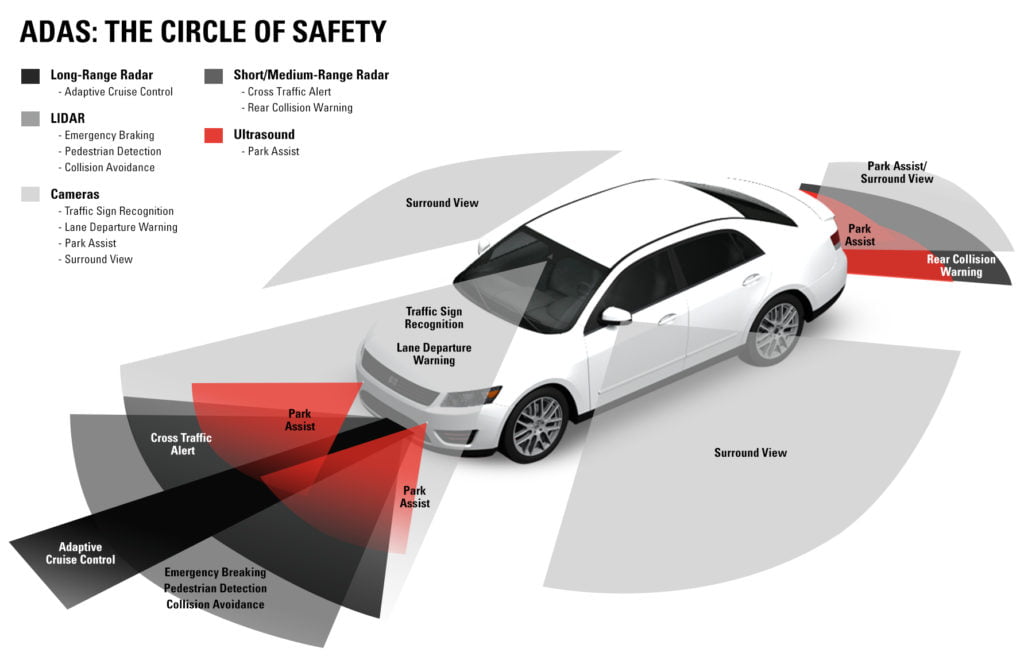

In automotive safety systems, MEMS accelerometers are instrumental in detecting and responding to sudden changes in vehicle motion. These sensors are integrated into airbag deployment systems, rollover detection systems, and pre-crash detection systems, enabling timely activation of safety measures to mitigate the severity of collisions and protect vehicle occupants. MEMS accelerometer also facilitates the implementation of advanced driver assistance systems (ADAS), such as lane departure warning, adaptive cruise control, and collision avoidance systems, by providing accurate motion sensing capabilities essential for autonomous driving functions.

5. Future Trends and Challenges:

MEMS accelerometers typically consume less power than quartz accelerometers, making them well-suited for automotive applications where energy efficiency is important. Lower power consumption helps to extend battery life in battery-powered vehicles or reduce the load on the vehicle's electrical system in conventional vehicles.

More importantly, MEMS accelerometer can be mass-produced using semiconductor fabrication techniques, resulting in lower manufacturing costs compared to quartz accelerometers. This cost-effectiveness makes MEMS accelerometer more economically viable for widespread adoption in automotive systems, contributing to overall affordability and accessibility of vehicle technologies.

As automotive technology continues to evolve, several trends and challenges shape the future landscape of MEMS accelerometer in the automotive industry. These include the integration of accelerometers with other sensor modalities, such as gyroscopes and magnetometers, to enhance sensor fusion capabilities and improve vehicle perception in autonomous driving scenarios. Furthermore, advancements in MEMS fabrication techniques and sensor packaging technologies are expected to drive improvements in sensor performance, reliability, and cost-effectiveness, further expanding the scope of applications in automotive systems.

Summary:

In conclusion, MEMS accelerometers have become indispensable components in the automotive industry, playing a pivotal role in enhancing vehicle dynamics, safety, and user experience. Their integration into various automotive systems enables precise motion sensing and control, facilitating the implementation of advanced safety features and autonomous driving functionalities. As automotive technology continues to evolve, MEMS accelerometer is poised to remain at the forefront of innovation, driving further advancements in vehicle performance, safety, and efficiency.

The ER-MA-5 MEMS accelerometer, developed by Ericco, boasts small dimensions, lightweight construction, and low energy consumption, making it highly versatile for applications within the Automotive Industry. Its adaptability extends beyond automotive contexts, finding utility in vibration detection, attitude control, security alarm systems, consumer electronics, motion recognition, and status recording. When coupled with gyroscopes and magnetometers, these accelerometers contribute to the creation of Inertial Measurement Units (IMUs), enabling comprehensive motion tracking and orientation sensing capabilities.

More Technical Questions

1. Mechanism Analysis of Q-Flex Accelerometer Instability

2. Quartz Accelerometers Advance Aircraft Performance and Safety

3. Parameters to Evaluate Performance of Quartz Flexure Accelerometers

4. Factors Affecting the Stability of Q-Flex Accelerometers

5. Structure Design of High Precision Quartz Flexible Accelerometer

6. Methods to Maintain the Long-Term Performance of Quartz Flexure Accelerometers