MEMS gyroscope is a kind of solid wave gyro, which is usually processed by micro and nano manufacturing technology, and has the characteristics of small volume, high performance, low power consumption and mass. Since the birth of the world's first hemispherical resonator gyro in 1975, the harmonic oscillator topology of MEMS gyro has undergone the evolution from three-dimensional structure to two-dimensional structure. This article will introduce the development of MEMS gyroscopes, and the following will be explained from the development of a variety of gyroscopes and MEMS gyroscopes.

Development of a variety of gyroscopes

Inertial technology is an undisturbed, real-time, autonomous and continuous motion information sensing technology. Gyroscope is one of the core components of inertial navigation system, which can be used to measure the motion angle or angular velocity of an object. According to the working principle, the common gyroscopes can be classified into rotor gyroscopes based on the fixed axis and precession of rotating mass, optical gyroscopes based on optical effects, vibration gyroscopes based on Coriolis force effect and atomic gyroscopes based on matter waves.

The traditional mechanical rotor gyroscope developed the earliest and its theoretical technology is the most mature, but it is large, expensive and short in life. The precision of optical gyroscope is high, especially the precision of laser gyroscope can reach the inertia level, but its volume is large, the manufacturing process is complex, and the manufacturing cost is high. Atomic gyroscope is a new gyroscope technology in recent years. It has the advantages of small size, low power consumption, strong anti-interference ability, and is expected to achieve inertial level accuracy. Compared with other kinds of gyroscopes, microresonant gyroscopes have the advantages of small size, low power consumption, low cost, easy integration, etc., and are widely used in aerospace, consumer electronics, navigation and guidance fields.

According to the topological structure of harmonic oscillator, the micromechanical vibration gyroscope can be divided into hemispherical microgyroscope, cylindrical microgyroscope, ring microgyroscope and mass block microgyroscope. With the development of microelectromechanical system (MEMS) technology, the traditional micromachining technology has greatly promoted the development of MEMS vibrating gyroscope. According to the different processing methods, the common processing technology of micro resonator gyro can be divided into three dimensional processing technology and plane processing technology. With the progress of material processing technology, the processing materials of micro-resonant gyroscope are becoming more and more diverse, among which monocrystalline silicon, fused quartz, diamond, polysilicon, silicon dioxide and other materials have become the focus of research in various countries.

Development history of MEMS gyroscope

Although ring-shaped MEMS gyroscope has better performance and simpler machining method, its performance is limited by higher angular random walk due to its lower modal mass, smaller angular gain and shorter ring-down time. Because the geometry of a planar MEMS gyro sensor is determined by lithography steps during machining without the need for assembly and alignment steps, it is feasible to design complex mechanical structures with multiple moving parts to achieve low-cost mass manufacturing, stiffness and damping symmetry, quality factors greater than 1 million, and ring-down times of more than a few minutes. The four-mass MEMS gyroscope has a completely symmetrical structure and operating mode, which can meet the above criteria. The angular gain of the operating mode of the four-mass MEMS gyroscope is 0.75, which is close to the theoretical 1. For ring microgyro, the angle gain of n=2 mode is about 0.37, and the angle gain of n=3 mode is only about 0.17. The four-mass MEMS gyro is the planar micromechanical gyroscope with the highest performance limit reported at present.

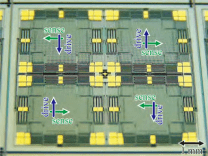

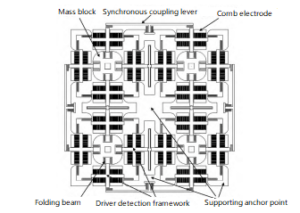

In 2010, the University of California, Irvine, proposed a completely symmetrical four-mass microgyro structure, as shown in Figure 1. Similar to the two-mass microgyro, the mechanical structure of the four-mass microgyro consists of four identical symmetric decoupled mass blocks, a pair of antiphase synchronous lever mechanisms for driving and detecting modes, and a curved beam between linearly coupled teeth. The architecture of the four-mass block microgyroscope is built on a two-mass design and can be thought of as a two-lever-type two-mass tuning fork gyroscope, with additional linear bent beams and inverting lever mechanisms. Due to the symmetry of the device, the driving mode and the detection mode are symmetrical, and full angle measurement can be achieved. In the following years, the institute conducted a lot of research on the theoretical design, packaging technology, control theory and full angle control of four-mass microgyro. At present, the quality factor of the gyroscope of this structure has been increased from the original 640,000 to more than 2 million, the zero bias stability has reached 0.065(°)/h, and the angular random walk is 0.0058(°)/√h, which shows the ability of inertial-level navigation.

Figure 1 Four-mass micromachined gyroscope

In 2016, Taheri-Tehrani et al. designed an epitaxial package four-mass micro-gyroscope with a size of only 2mm×2mm, which is only 1/16 of the size of the four-mass micro-gyroscope prototype proposed before, as shown in Figure 2. The structure has a quality factor of about 85000, and combined with closed-loop amplitude control and orthogonal compensation circuits, it can achieve an angular random walk of 0.42×10-3(°)/s/VHz.

Figure 2 Four-mass microgyroscope in epitaxial package

In 2016, Tsinghua University proposed a centrosymmetric four-mass harmonic oscillator (CSQMG) structure. The CSQMG consists of four mass blocks distributed along the circumference, which are connected by Y-beams. The center of gravity of the whole mechanism is at the very center of the structure, supported by a central anchor point. Each mass block has four electrodes for driving, detecting and adjusting. Subsequently, the structure parameter optimization, dynamic modeling and analysis, parameter driving and other technologies have been studied, and good results have been achieved.

In 2018, Xi 'an Flight Control Research Institute of Aerospace Industry proposed a ring-distributed four-mass micro gyroscope. The center of the structure is a ring coupled beam, four mass blocks are distributed along the ring beam and connected with each other through the ring coupled beam. Each mass block contains a drive frame, a lumped mass block and a detection frame. With a completely symmetrical structure, differential detection can be performed. The structure has a quality factor of 200,000 and a zero bias stability of better than 4(°)/h.

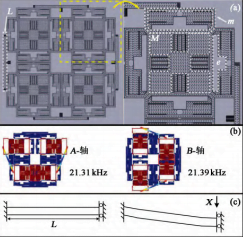

In 2018, the Singapore Institute of Microelectronics proposed a four-mass microgyroscope with a symmetrical structure. As shown in Figure 3, the structure consists of four identical mass blocks, which are connected by a central coupled spring and four conical rods. The gyroscope adopts synchronous inverse driving mode and differential detection, which can reduce the common mode signal caused by acceleration and vibration to a great extent.

Figure 3 A four-mass microgyroscope with symmetrical structure

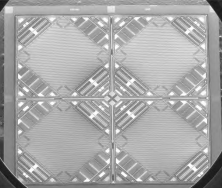

In 2020, Shanghai Jiao Tong University proposed a new structurally decoupled four-mass microgyroscope structure. As shown in Figure 4, the structure adopts the design of comb electrode and push-pull method to eliminate the double frequency component of electrostatic driving force, and the folded beam structure is simulated and analyzed and optimized, and the ideal decoupling effect is achieved through the design of two degrees of freedom.

Figure 4 Shanghai Jiao Tong University four-mass micro-gyroscope

Conclusion

This paper lists the advantages and disadvantages of different kinds of gyroscopes, and focuses on the development status of four-mass MEMS gyroscopes. Compared with ring-shaped gyroscopes, four-mass micro-gyroscopes have higher angular gain and modal mass, so they have lower angular random walks. Its completely symmetrical structure design has become a research hotspot in recent years.

As a member of the research and development of mass MEMS gyroscope, Ericco has conducted in-depth research on MEMS knowledge and developed a number of high-performance MEMS gyroscopes. For example, ER-MG2-50/100 is a navigation-grade north-finding MEMS gyroscope with an angular velocity of 0.0025-0.005°/√hr. The ER-MG-067 is also a high performance MEMS gyroscope, but it is a tactical grade gyroscope, and the angular velocity random walk can achieve <0.125°/√hr. Similarly, individual mass blocks of gyros can also form two - and three-axis MEMS gyros, such as ER-2MG-02 and ER-3MG-06, both high performance two - and three-axis gyros.

If you are interested in learning more about MEMS gyro, please contact us.

More Technical Questions

1.Integrated method of three-axis MEMS gyroscope

2.Bandwidth test method of MEMS gyroscope

3.Impact resistance technology of MEMS gyroscope

4.Research on driving mode of MEMS gyroscope

5.Analysis of drive loop noise of MEMS gyroscope

6.Comparative analysis of integrated modes of three-axis MEMS gyroscope

Products in Article