MEMS gyroscope based on silicon materials have the advantages of miniaturization and low power consumption, and are the main sensors for attitude measurement, which are widely used in consumer electronics, industrial and aerospace equipment, etc., among which high-precision MEMS gyroscopes have been the focus of attention in academia and high-end equipment manufacturing. One of the main indexes to evaluate the precision level of gyroscope is the bias stability, so improving the bias stability of gyroscope is very important for the development of high precision gyroscope. This paper will describe the bias stability of MEMS gyroscope, and the following will introduce the concept and calculation method of bias stability.

Concept and research results of bias stability of MEMS gyroscope

Bias stability refers to the stability of the output signal of the MEMS gyroscope at zero input angular velocity. The better the bias stability, the higher the gyroscope accuracy. Temperature parameters have been clearly identified as the main driving factor for the bias stability of MEMS gyroscope. Because material characteristics and structural stress will change with temperature changes, vibration characteristics such as resonant frequency and quality factor of MEMS gyroscopes will change accordingly, which will affect the bias stability of the gyroscope.

The effect of temperature on the bias stability of different gyroscopes shows heterogeneity and complexity, which makes it difficult to compensate the back end. The bias drift of MEMS gyro at 15-45 ℃ was measured when the bias stability calibration compensation was studied. The bias drift before and after calibration was negatively correlated with temperature. When the temperature compensation method of silicon MEMS gyro on chip is studied, fixed-point constant temperature experiment and continuous temperature rate experiment of gyro output are carried out, and it is concluded that the variable temperature rate has no obvious influence on the output of gyro. When studying the temperature characteristics and performance improvement of MEMS gyro with wide temperature range, it is concluded that the bias stability of silicon micromechanical gyroscope at high temperature is higher than that at low temperature, and the bias stability in the whole temperature region is much higher than that at high and low temperature. At the same time, the bias of the gyroscope under the alternating temperature load of -25-50 ℃ is tested. The bias of the gyroscope shows the same trend of first rising and then decreasing in the constant temperature section, while the zero bias does not show a linear trend in the variable temperature section, which brings great difficulty to the subsequent compensation. Previous studies have proposed a method to improve the temperature sensitivity of gyro error based on electrostatic force compensation, and built a gyro error temperature characteristic test system to verify the effectiveness of the method. In order to solve the problem of bias drifting with temperature, a bias temperature compensation method based on MEMS micromechanical gyroscope drive resonance frequency is proposed. The temperature influence modeling analysis of bias is carried out. After temperature compensation, the bias stability is improved by 22 times. The bias output of the self-developed silicon micromachined gyroscope is tested at -40-60 ℃, and the two are basically negatively correlated. After third-order compensation, the bias stability of the gyroscope is controlled within 10.2(°)/h.

A method for calculating the bias stability of MEMS gyroscope

At present, there are mainly 1σ method and Allen variance method to calculate the bias stability of gyroscope. Allen variance will affect the bias stability of white noise,

The 1/f noise and temperature drift are decomposed and calculated, and the 1/f noise calculation results are used as the measurement index of bias stability, which is suitable for the long-term bias stability test evaluation of low output rate gyroscopes. The 1σ method takes all the above factors into consideration and is suitable for the evaluation of the bias stability of gyroscopes with higher output rate.

The formula for calculating bias stability by the 1σ method is defined as:

![]()

Where: σ is the standard deviation of the zero-point voltage output of the gyroscope in statistical time, mV; SF is the scale factor of the gyroscope, mV·[(°)/s]-1

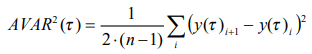

The Allen variance method's formula for calculating the stability of zero bias is defined as:

Where AVAR(τ) is the Allan variance as a function of average time τ.

Conclusion

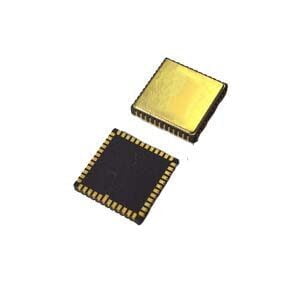

In this paper, bias stability, a very important parameter of MEMS gyros, is introduced. The concept, research results and calculation methods of bias stability are described. The size of bias stability can tell whether the performance of MEMS gyro is excellent. For example, the ER-MG2-50/100 is a high-performance north seeking MEMS gyroscope with bias stability (1σ 10s) of 0.05-0.1deg/hr and zero-bias stability (1σ 1s) of 0.15-0.3deg/hr. The ER-MG2-300/400 is a high-precision navigation MEMS gyroscope with zero-bias stability (1σ 10s) of 0.15-0.5deg/hr and zero-bias stability (1σ 1s) of 0.5-1.5deg/hr.

To learn more about MEMS gyroscopes, please contact us.

More Technical Questions

1.Integrated method of three-axis MEMS gyroscope

2.Development history of MEMS gyroscope

3.MEMS gyroscope processing technology

4.Research on driving mode of MEMS gyroscope

5.Stochastic error modeling method of MEMS gyroscope

6.Signal Denoising Principle And Evaluation Index of MEMS Gyroscope

Products in Article

High precison MEMS Gyroscope

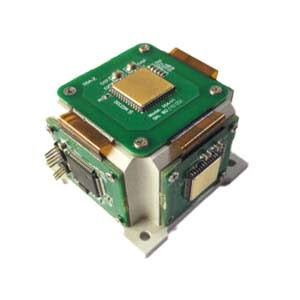

High Precision Stable-Control MEMS IMU