MEMS sensor includes MEMS gyroscope and MEMS accelerometer, which have the characteristics of small size, light weight, low power consumption and low cost. MEMS inertial measurement unit (MEMS IMU) is a combination of these two MEMS sensors, and the system can be developed by adding algorithms on the basis of them. MEMS north finder is a system implementation based on IMU, which can realize north finding function in oil logging, mining and other fields. MEMS gyroscope is a mechanical gyroscope based on Coriolis force, because of its advantages that other types of gyroscopes do not have, so it has become the first choice in all walks of life.

As the oil and gas industry recovers from a prolonged downturn, there is a strong need for operators to increase downhole intelligence, improve technical reliability, speed up drilling and reduce the cost of connecting downhole operations to each other, according to McCombs.These factors together initiate a new era of directional drilling sensor technology based on MEMS sensor.

In the history of oil and gas drilling, the basic principles and methods involved in drilling sensor technology have changed only twice.The invention of borehole sensors first appeared in the 1920s.Before that, the industry was largely blind to drilling.Drilling instruments were developed using simple techniques, such as acid in a bottle to corrode the glass out of the meniscus, or other simple mechanical means to measure deviation in the well.

In the 1970s, with the invention of magnetic guidance tools, a major revolution swept the industry, based on principles that most modern directional drilling tools still adhere to.However, we are now witnessing the dawn of a new era in which directional drilling sensors based on MEMS sensor technology are being accepted as reliable alternatives to drilling.

Why MEMS sensor?

With MEMS sensor technology, man creates tiny mechanical devices according to his most vivid imagination.Imagine gears, transmissions, clutches, actuators, and even miniature turbine engines as big as fingernails.But how do humans do it at the micro level? Even the modern precision computer controlled machine cannot meet the micro - scale of MEMS devices.

MEMS sensor has the following advantages:

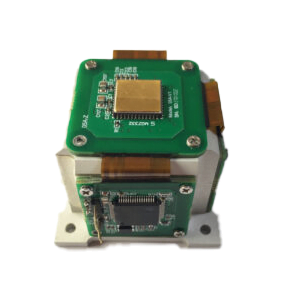

1. Small size and light weight. Ericco's MEMS gyroscope and accelerometer are 11×11×2mm in size, which is the size of a nail clipper, and the quality is far lower than other gyroscopes.

2. Low cost, easy mass production. Because of the low cost and simple process of MEMS sensor, it is easier to mass produce. It is a great choice for areas where costs need to be controlled.

3. Low power consumption. Ericco's MEMS sensors consume only 0.2w.

4. Can work in harsh high temperature environment, strong vibration resistance.

5. The working temperature is gradually increased to meet the needs of many fields. For MEMS gyroscope, most of the working range is -40℃~+85℃, in order to meet the needs of oil logging, directional drilling and other fields, better adapt to the downhole high temperature and harsh environment, the working temperature of MEMS gyroscope is also gradually increased. For example, ER-MG2-022 is a technical evolution, it is a high temperature north seeking MEMS gyroscope designed for gyrotools, its operating temperature can reach a maximum of 125 ° C, which realizes a great breakthrough in operating temperature.

6. The precision level can meet the needs of multiple fields. MEMS sensors are classified into consumer, tactical and navigational levels. Consumer-grade MEMS sensors have low accuracy and are mostly used in automobiles, smart phones and other fields. Navigation-grade MEMS sensors have the highest accuracy and are mostly used in high-precision fields such as drones and aerospace. The accuracy of the tactical level is slightly lower than that of the navigation level, which can meet the needs of oil logging, drilling, mining, mapping and other fields.

Comparison of MEMS sensors with different precision

We take MEMS gyroscope as the main comparison object. In the field of directional logging, the north seeking MEMS gyroscope that can find the north will mainly be used. The following are four navigation levels of north seeking MEMS gyroscopes ER-MG2-50/100,ER-MG2-200 and ER-MG2-022, through the table we can understand the obvious differences between the accuracy and performance.

| Parameters | ER-MG2-50 | ER-MG2-100 | ER-MG2-200 | ER-MG2-022 |

| Measurement range(deg/s) | 50 | 100 | 200 | 100 |

| Bias instability(deg/hr) | 0.01 | 0.02 | 0.02 | 0.02 |

| Bias stability(1σ 10s)(deg/hr) | 0.05 | 0.1 | 0.1 | 0.1 |

| Bias stability(1σ 1s)(deg/hr) | 0.15 | 0.3 | 0.3 | 0.3 |

| Angular random walk(°/√h) | 0.0025 | 0.005 | 0.005 | 0.025 |

| Scale factor repeatability (1σ)(ppm) | 50 | 50 | 100 | 100 |

| Temperature(℃) | -40~+85 | -40~+85 | -40~+85 | -40~+125 |

I hope you can learn more about MEMS sensor through this article, if you want to know more, please contact us.

More Technical Questions

1.Integrated method of three-axis MEMS gyroscope

2.Development history of MEMS gyroscope

3.MEMS gyroscope processing technology

4.Evolution of resonant structure of high precision MEMS gyroscope

5.MEMS Gyroscope: Sensitive Structure | Detection Circuit | Integrated Package

6.Research On Segmented North Seeking Orientation Based On MEMS Gyroscope