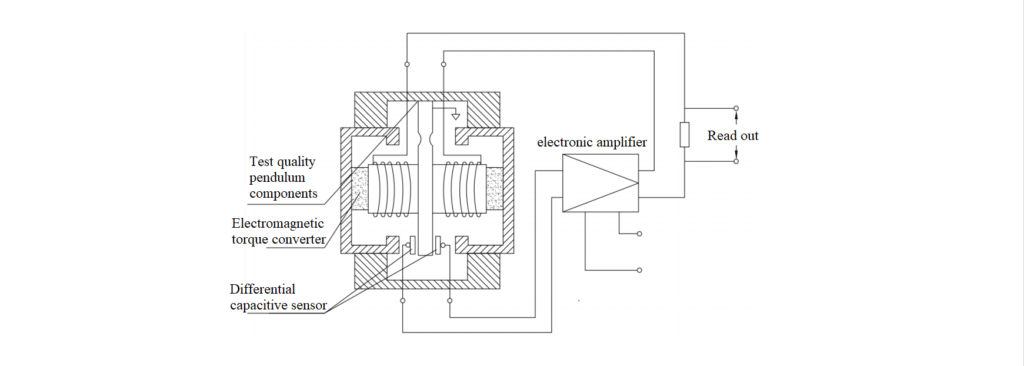

The quartz flexible accelerometer belongs to the force balance pendulum structure accelerometer, and its performance indicators can meet the requirements of most working environments. Therefore, it has a wide range of applications in fields such as aerospace, defense, and military.

However, as one of the core components of an inertial navigation system (gyroscope and accelerometer), its performance (especially its operational accuracy) often directly affects whether the entire system can operate normally. Consequently, exploring methods to improve the measurement accuracy of accelerometers has become a crucial aspect of research in the field of inertial technology.

The measurement accuracy of accelerometers is not only related to their own design schemes, technical processes, and manufacturing materials but also to the working environment in which they are located, especially the operating temperature.

Changes in the working environment temperature can cause thermal expansion and contraction of components and changes in material physical parameters, primarily reflected in their scale factor and zero bias. It has become an important aspect constraining the performance of accelerometers in the current development process.

Therefore, it is necessary to qualitatively analyze the influence of working environment temperature on the performance of accelerometers and then study methods to improve the output accuracy of accelerometers based on this analysis.

1.Analysis of Temperature Characteristics of Quartz Flexible Accelerometer

Related research results show that the temperature has the following two main effects on the operational accuracy of quartz flexible accelerometers:

1.1 Magnetic Field Variation

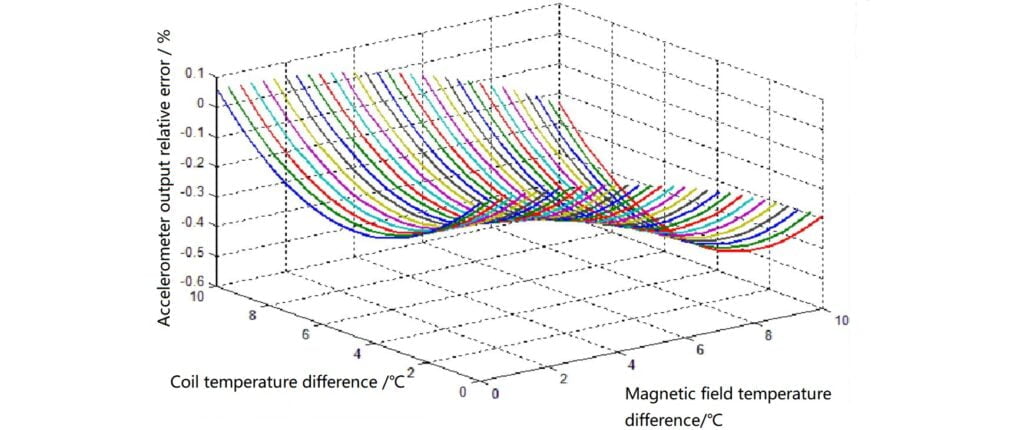

Some internal magnetic fields of accelerometers will undergo subtle changes with the external working environment temperature, resulting in inaccurate scale factors of accelerometers. At the same time, zero drift may also occur, and even the inherent parameters of the system such as damping coefficient and elastic modulus may also drift slightly with temperature.

1.2 Current Variation

The torque coil will generate feedback current during operation, causing the coil temperature to rise due to the thermal effect of the current. This change in coil temperature will in turn make the temperature distribution inside the meter shell uneven, leading to changes in the magnetic material parameters, ultimately reflected in the scale factor.

Additionally, as the temperature increases, the area of the coil also increases, leading to an increase in the magnetic flux enclosed by the coil, i.e., an increase in nonlinear error. Finally, the support arm may also undergo deformation, which will cause the signal sensor to drift again, and meanwhile, the change in arm length or moment of inertia will also cause a deviation in the initial value of the pendulum effect, resulting in serious drift in the scale factor.

In summary, temperature changes will affect the internal magnetic field parameters and core structure of quartz flexible accelerometers, ultimately manifested in the drift of scale factors and zero biases of accelerometers, thereby causing output errors.

2.Solutions to Temperature Influence on Quartz Flexible Accelerometers

Currently, in practical engineering design, to mitigate the impact of working environment temperature on quartz flexible accelerometers, the following methods are usually adopted for improvement:

2.1 Material Aspect

Consider using materials that are insensitive to temperature from the perspective of material and improve the thermal design of inertial devices to reduce the sensitivity of the entire system to temperature. For example, using components with negative temperature coefficients to offset or compensate for changes in positive temperature coefficient materials in accelerometers.

2.2 Mathematical Compensation Model

Qualitatively and quantitatively analyze the temperature characteristics of inertial devices to establish a mathematical compensation model that meets certain accuracy requirements. Based on the mathematical calculation results, real-time compensation for deviations caused by temperature changes can be performed through software algorithms.

2.3 Improvement of Accelerometer Working Environment

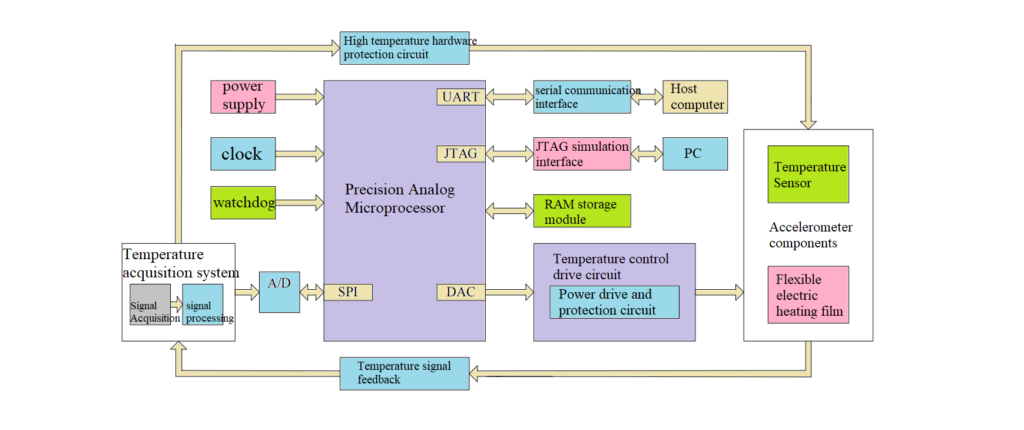

Improving the working environment of accelerometers to minimize the temperature variation during operation, such as using hardware constant temperature structures to operate in a constant temperature environment.

The first method of improvement mainly focuses on improving from the perspective of materials and design structures. It seeks to fundamentally identify the causes of accelerometer temperature drift and corresponding solutions. Currently, many researchers and technicians have conducted related research on this.

The second method of improvement considers and improves from the perspective of software algorithms. It establishes a relatively sophisticated temperature mathematical compensation model through qualitative and quantitative analysis of experimental data to perform real-time compensation for errors caused by temperature changes. At the present stage, many experts and scholars are also discussing and researching these issues.

The ER-QA-03C accelerometer uses a temperature sensor, and operators can compensate for deviations and scale factors based on it to reduce the impact of temperature factors.

The last method of improvement controls temperature changes through external hardware structures, mainly to make accelerometers work in a constant temperature closed-loop environment to isolate the influence of external uncertain conditions.

Compared with the first two methods, which have disadvantages such as complex design, long cycle, and high cost, the third hardware temperature control method not only has low cost and easy implementation but also has strong universality while maintaining high accuracy, thus it has been widely used in engineering practices at home and abroad.

3.Summary

This article analyzes the influence of temperature on quartz flexible accelerometers and the corresponding solutions. Temperature changes mainly affect the internal magnetic field parameters and current of accelerometers, leading to drift in scale factors and zero biases, thereby causing output errors. To address this issue, solutions such as material improvement, mathematical compensation models, and improvement of working environments are proposed.

In particular, the ER-QA-03C mentioned earlier has dimensions of Ф18.2X23mm, with a scale factor of 1.0±0.2 mA/g. The zero offset repeatability of the ER-QA-03C1 series is ≤15 μg, and the scale factor repeatability is ≤15ppm. In addition to aerospace applications, it can also be used for static and dynamic acceleration measurements.

More Technical Questions

1. Failure Mode Analysis of Quartz Flexure Accelerometer

2. Improvement of Temperature Stability of Quartz Flexible Accelerometers

3. Quartz Accelerometers Advance Petroleum Logging Precision

4. Analysis of I/F Conversion Circuit of Quartz Accelerometer

5. MEMS Accelerometer Installation Error Correction Method

6. How to Improve the Impact Resistance of Quartz Accelerometer

Products in Article